Austrian upholstery manufacturer

Our part

in this

project

The task

The requirements:

- Large-scale replacement of the existing 3,000 kW gas boiler

- Reuse of the production waste as fuel

- Use of the previous structure for fuel extraction systems

- Modernisation of the safety technology

Our solution

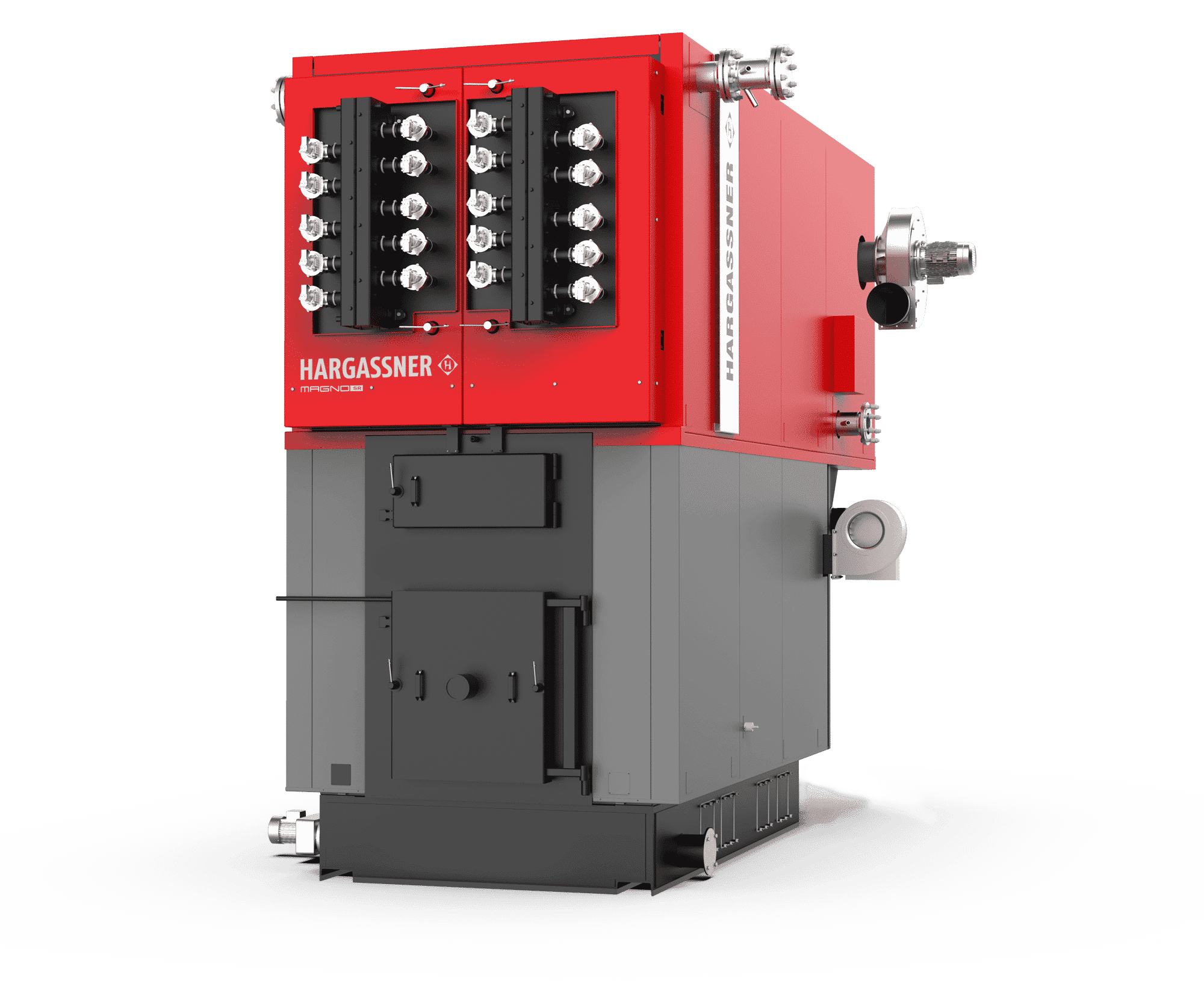

With the Magno-SR 2.000 industrial heating system for the greatest heat demand, the Austrian upholstery manufacturer relies on state-of-the-art biomass heating technology for durable high-performance operation.

- Industrial heating system Magno-SR 2.000 (2 MW)

for wood chips, sawdust and bark - The best possible use & modernisation

of the old stock

The requirements of our customer were great, as was the solution presented by Hargassner Industry. In the course of the project planning, it was decided to install a Magno-SR with 2 MW output. So far the only giant of its kind in Austria. As far as the fuel supply system incl. silo was concerned, the old system was to be retained as far as possible; only the safety technology had to be brought up to date. The construction of an additional foundation exacerbated the already difficult space situation, which required accurate and precise work during assembly: the boiler was lifted over the roof into the existing hall with a 150 t crane and had to be pushed far under an existing metal scaffolding with a precise fit by means of a chain hoist on three metre metal rollers.

A major benefit for the upholstery manufacturer is that the production waste from its own manufacturing can be used as fuel. This saves enormous amounts of CO2, as the Hargassner Magno-SR 2000 largely replaces the existing 3,000 kW gas boiler – an important step towards climate protection & sustainability.