Energy-saving and cost-cutting

ECO fuel extraction system - robust and reliable

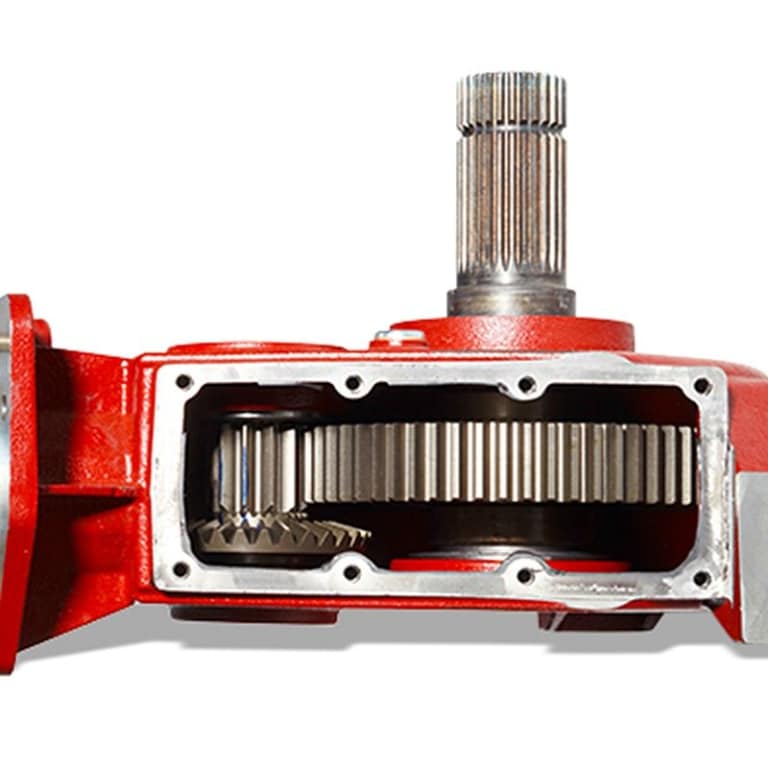

Thanks to a low drive output of just 0.18 kW (0.30–0.38 kW for 70–330 kW boilers) and a robust, high-efficiency spur gear, the fuel extraction system saves a huge amount of energy and therefore lowers electricity costs. You can save as much as 67% in electricity costs compared to those for conventional fuel extraction systems. With the excellent gear efficiency of over 90%, it clearly outperforms conventional worm gears. The new modular design ensures that the auger, along with its trough and removable cover, is easy to use.

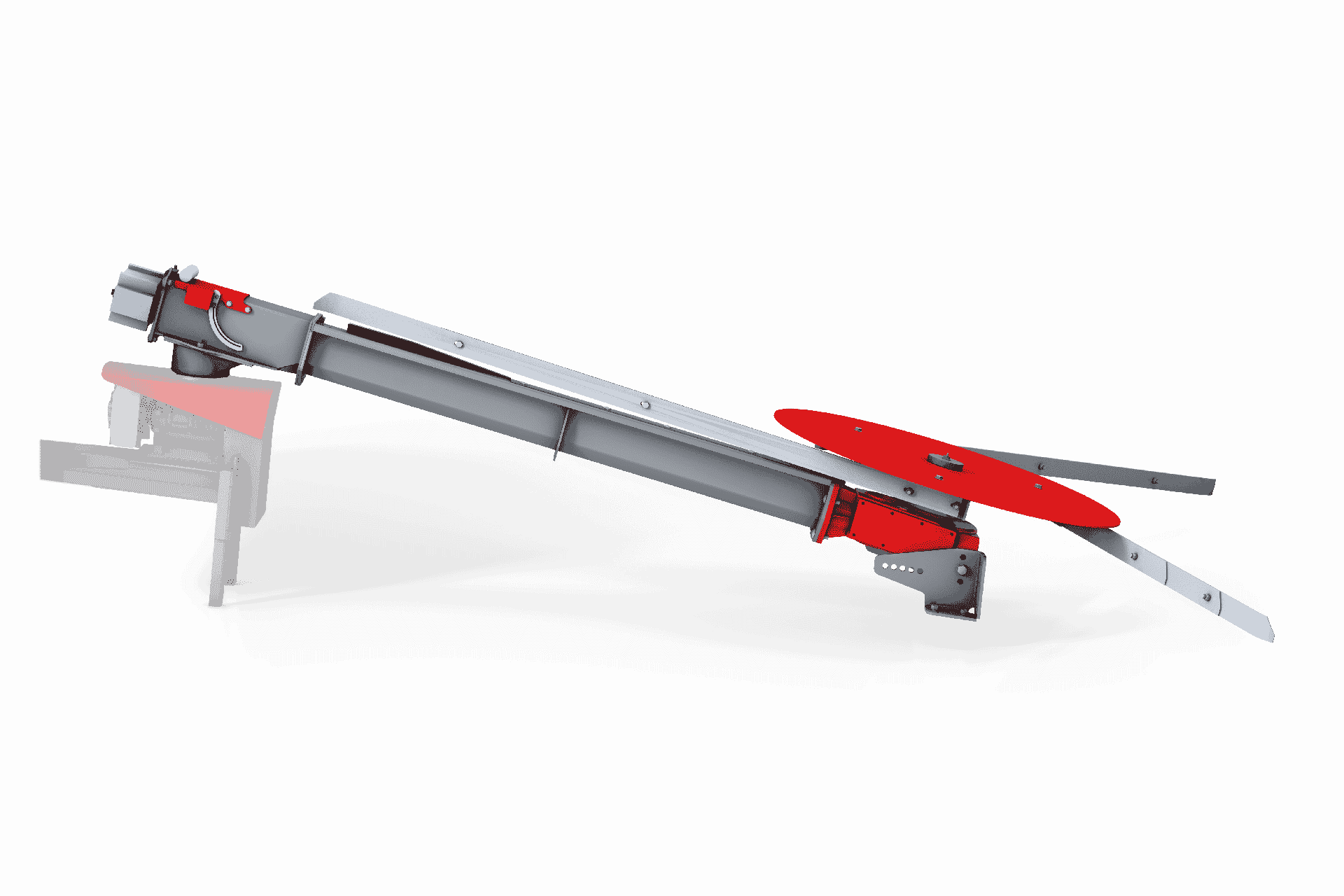

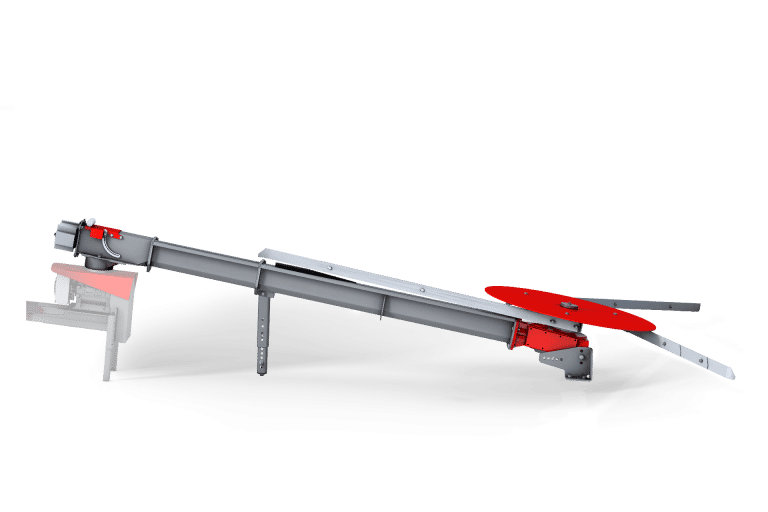

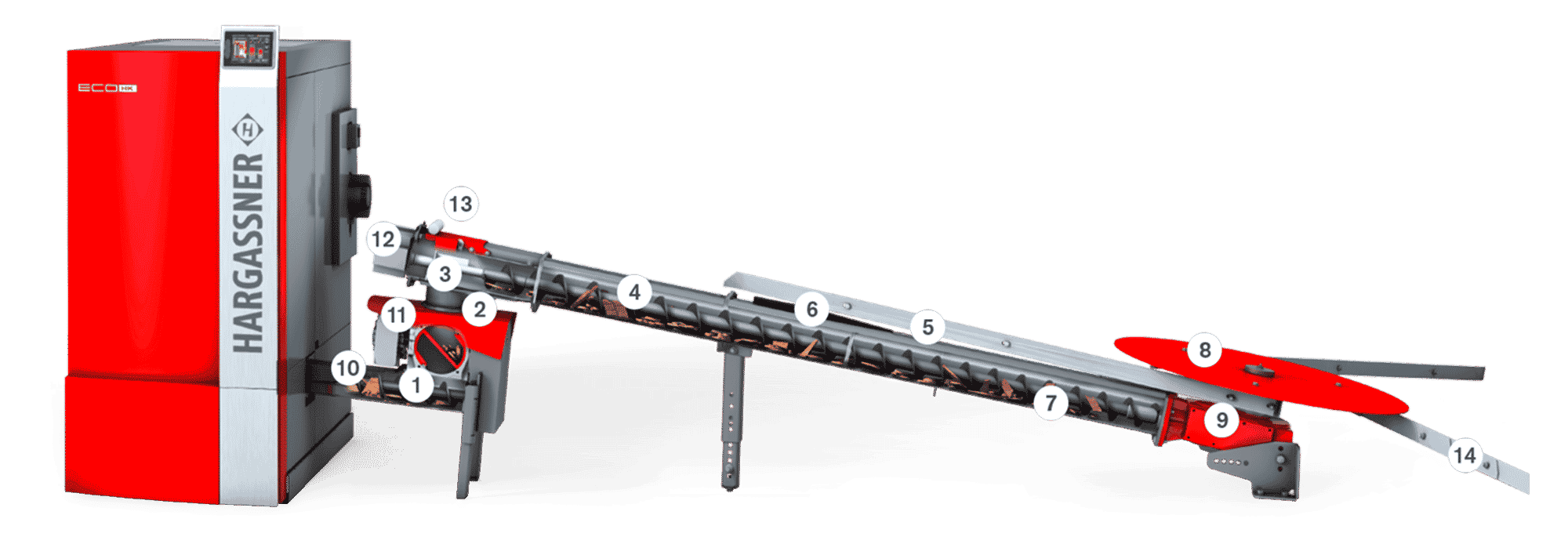

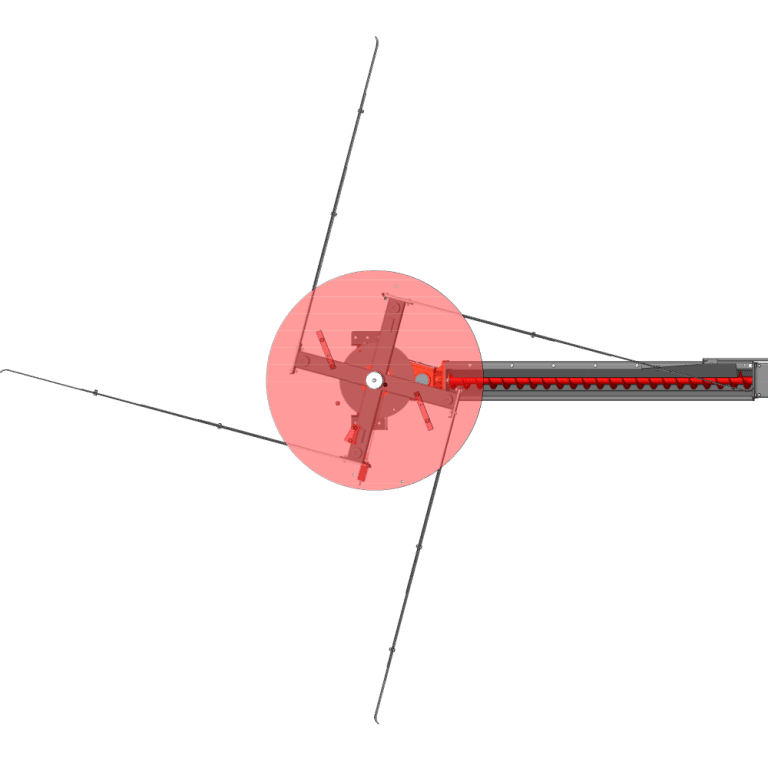

ECO fuel extraction system

Cross section & specifics

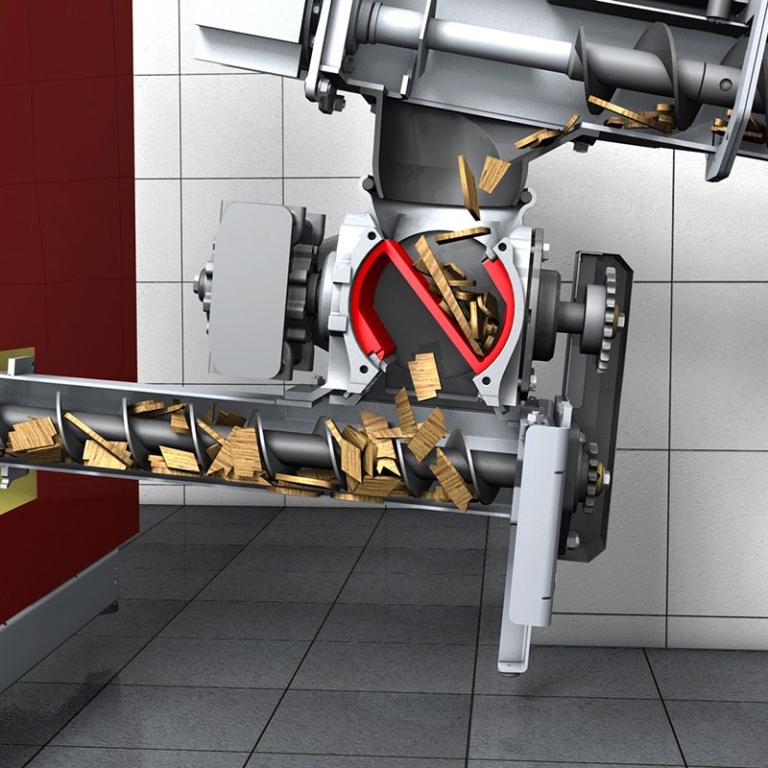

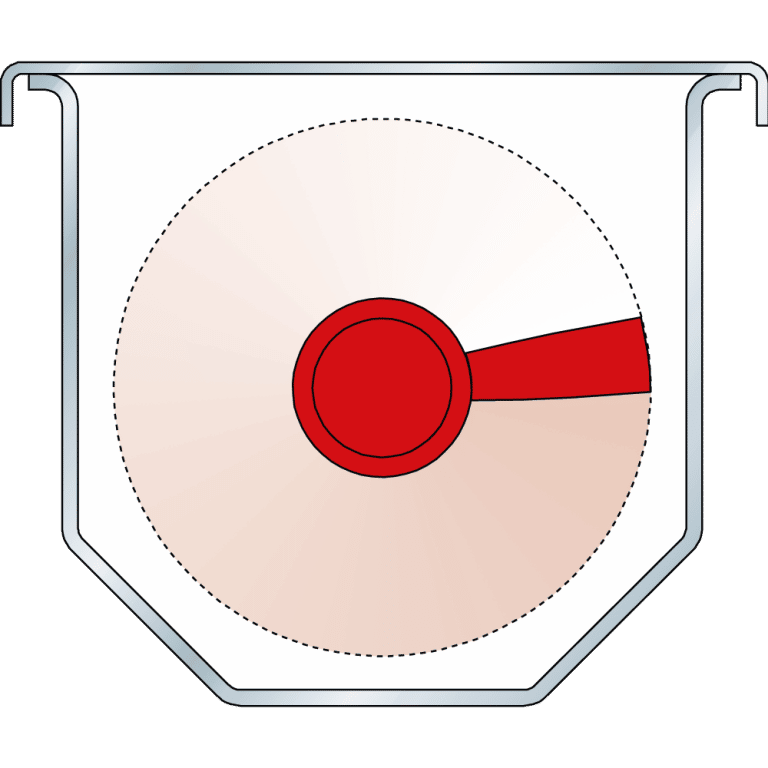

1 – Bicameral rotary valve in Z-form

2 – Ball coupling

3 – Breaker box

4 – FE system extensions (modular design)

5 – Special spring blade layout

6 – Effective wood chip inlet bracket

7 – Extraction auger and shaft

8 – No-load disc

9 – Eco fuel extraction gear unit (spur gear)

10 – Stainless steel stoker auger (and pipe) with STM temperature monitoring

11 – Drive motor for the stoker auger and rotary valve

12 – Drive motor for the extraction auger and agitator

13 – Safety cover with a reverse function

14 – Floor agitator with spring blades

Worm gear

- friction loss

- low efficiency

Spur gear

- low friction loss

- high efficiency

Bicameral rotary valve in Z-form

- Chamber depth 18 cm / 22 cm

- 100% burn-back protection guaranteed

- For long pieces of wood

- Easy to replace

- Saves a lot of effort

- Has hardened cutting edges

Modular design

- Planning flexibility

- Auger extensions of 300 – 2000 mm

- Easy to transport and install

- Quicker and cheaper to maintain

- Individual auger parts can be replaced

Eco fuel extraction gear unit

- Maximum efficiency

- Energy-saving and highly efficient

- Durable

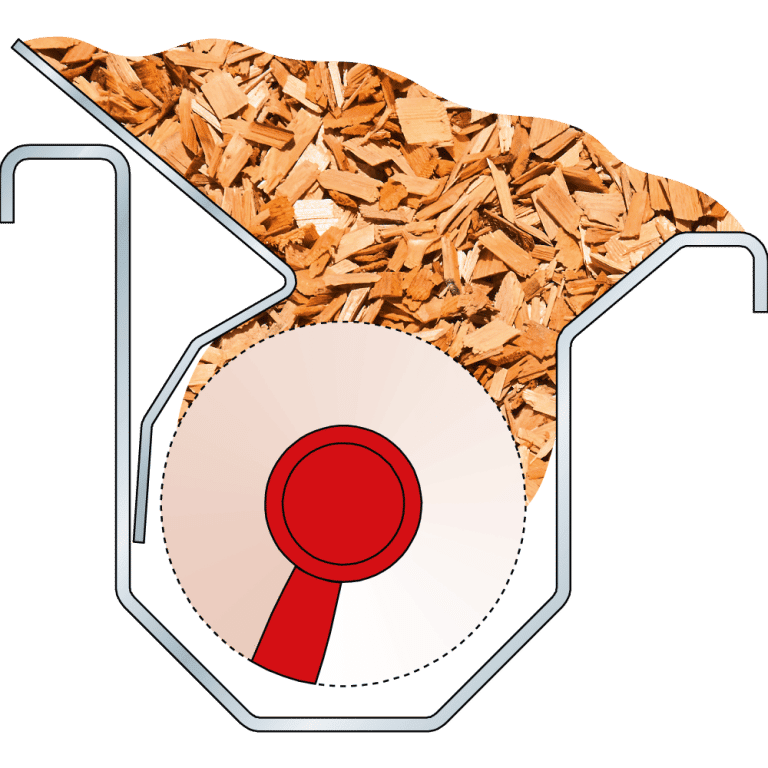

Hargassner no-load disc

- Effort required halved

- Disc remains still until the spring blades are retracted under the disc

- No hollow spaces created

- For extraction systems with Ø 4.5 m & 5 m

New auger and shaft

- Generously dimensioned

- 3 shaft sizes

140 mm / 180 mm / 260 mm - Optimized for boiler type

- No fuel jams

- Suitable for wood chips/pellets

Wood chip inlet bracket

- Optimum fuel supply

- Ideal amount of fuel in the auger shaft

- Max. fuel storage room emptying

- Less effort required and less wear and tear

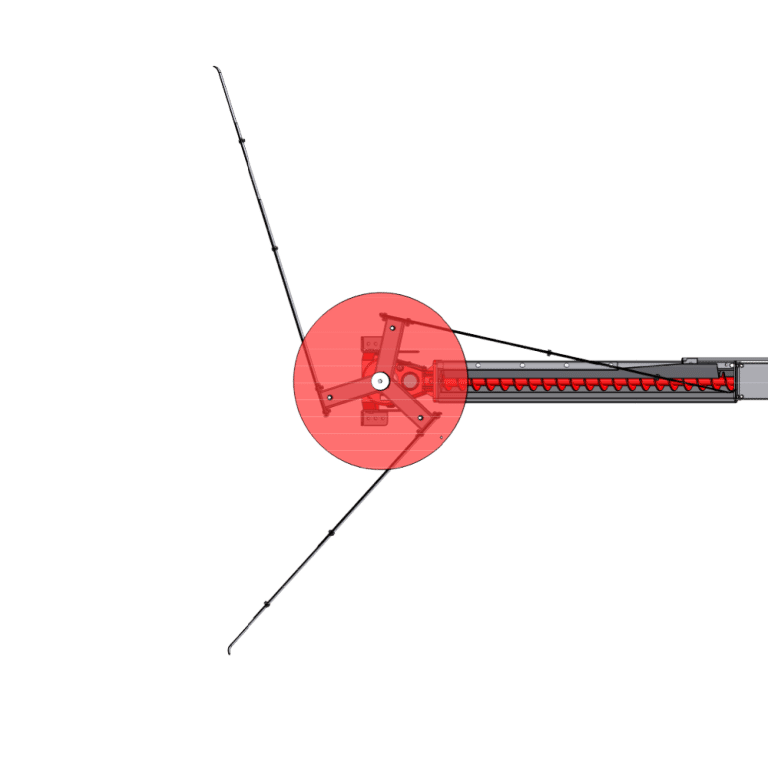

3-blade system

- Special spring blade layout upt to Ø 4 m

- Power-saving gear ratio 1:16

- Shaft 140 mm = Eco-HK 20–120

- Shaft 180 mm = Eco-HK 130–330

& Magno UF/VR 250–400

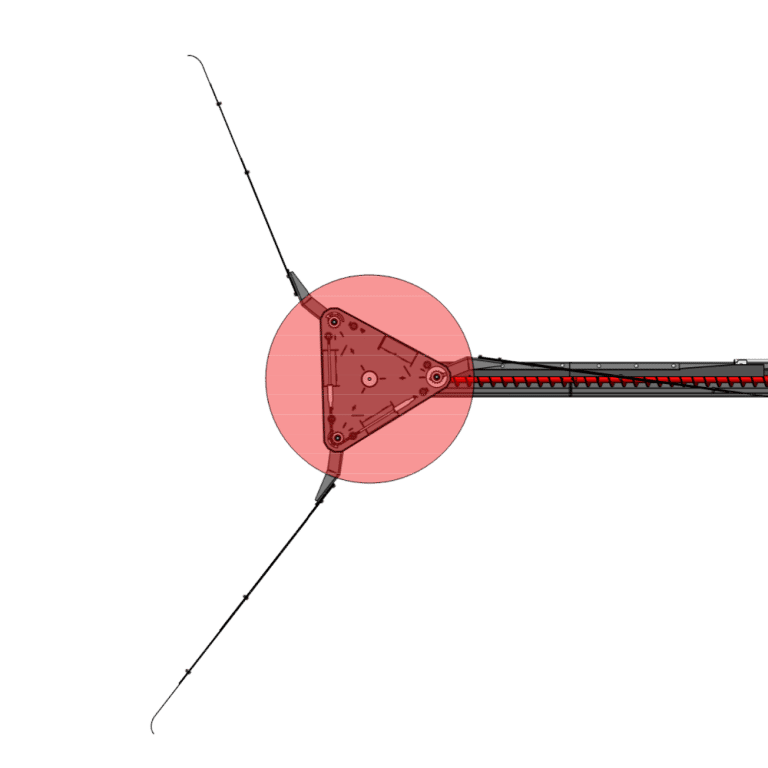

4-blade system

- Special spring blade layout up to Ø 4,5 – 5 m

- Hargassner no load disc

- Power-saving gear ratio 1:25

- Shaft 140 mm = Eco-HK 20–120

- Shaft 180 mm = Eco-HK 130–330

& Magno UF/VR 250–400

3-blade hinged arms

- Ø of 5.5 & 6 m

- Power-saving gear ratio 1:25

- Shaft 260 mm

= Magno UF/VR/SR 450–1400

Matching Hargassner spring blade systems to possible wood chip heating models and shaft sizes

| Spring Blade Layout | FE-Type | Eco-HK 20–120 | Eco-HK 130–330 | Magno UF/VR 250–400 |

Magno UF/VR/SR 450–1400 |

|---|---|---|---|---|---|

| Fuel Extraction System 3-blade system Shaft 140 / 180 |

200 , 250 , 350 , 300 , 400 |

✓ / – | – / ✓ | – / ✓ | – / – |

| Fuel Extraction System 4-blade system & no-load disc Shaft 140 / 180 |

450 , 500 | ✓ / – | – / ✓ | – / ✓ | – / – |

| Fuel Extraction System 3-blade hinged arms Shaft 140 / 180 |

550 , 600 | ✓ / – | – / ✓ | – / ✓ | – / – |

| Fuel Extraction System 3-blade hinged arms Shaft 260 |

450 , 500 , 550 , 600 |

– | – | – | ✓ |