Smart-HV &

Smart-PK

Convenient, affordable and flexible

Energy efficiency class: A+

- Cost-effective

- Automatic switch to pellets

- Simple, manual filling

- Up to 10 days of heating without refilling

Smart-Combi for wood log and pellets

Combi boiler system with perfect price-performance ratio

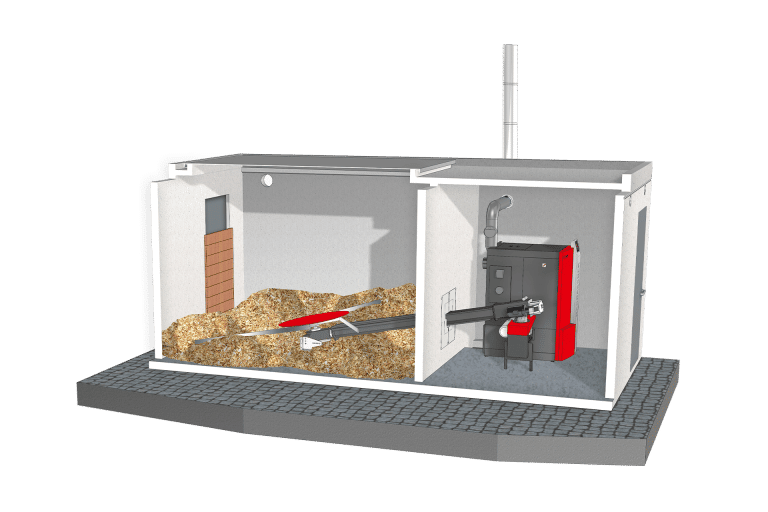

This cost-efficient Hargassner solution also available for the UK market consists of a Smart-HV wood log boiler and a Smart-PK pellet boiler that are both filled manually. Sophisticated combustion and control technology coupled with the automatic changeover from log wood to pellets makes the smart combi additionally convenient and efficient. The heat exchanger is also cleaned manually. If the wood log boiler is empty, the system will automatically switch to pellets. This combi option can run for up to ten days without being refilled.

Benefits:

Smart-HV & Smart-PK

- Cost-effective entry into the wood log-pellet combination heating system

- Perfect price-performance ratio

- Manual filling of the fuels - up to 10 days without refilling

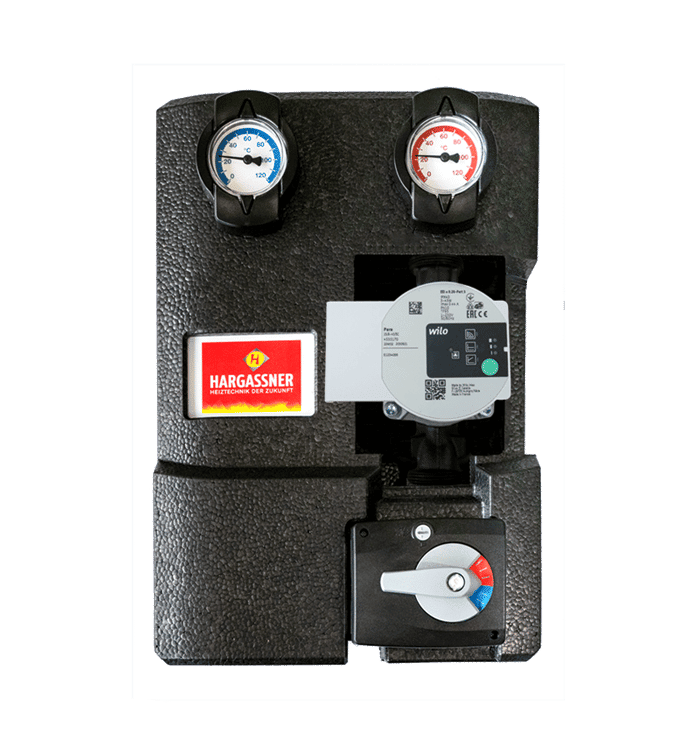

- Sophisticated fuel technology in both boilers

- Highest efficiency

- Fuel supply security for the future

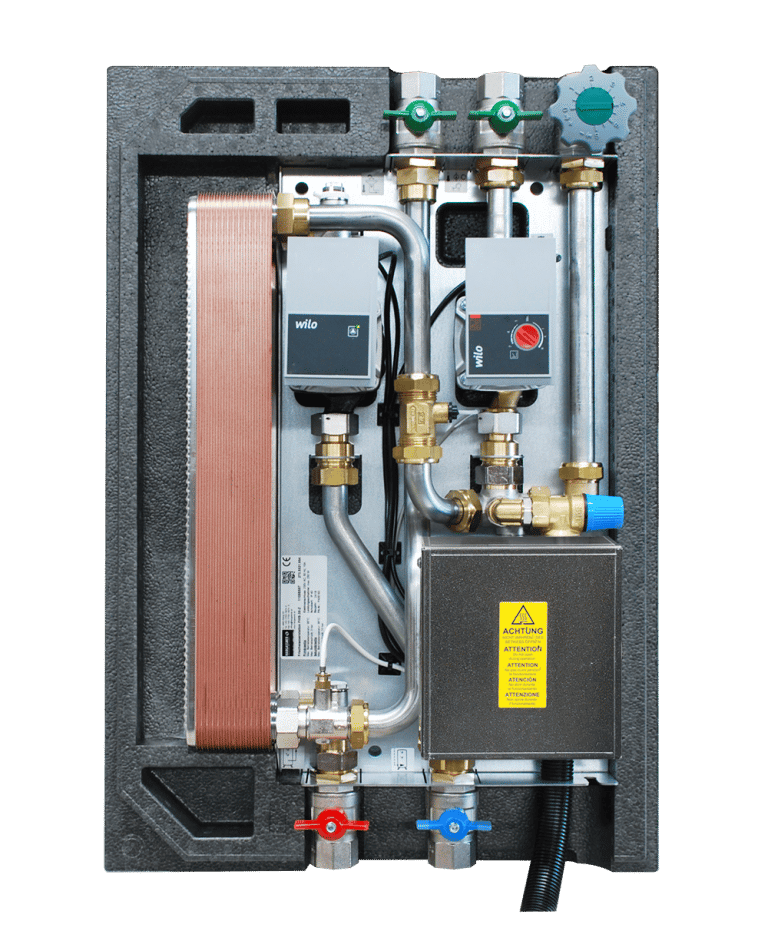

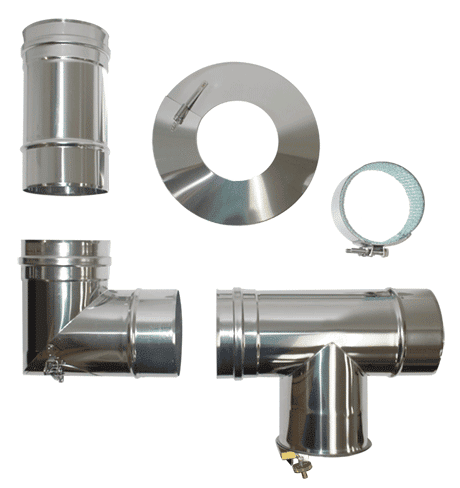

- Two seperate, efficient heat exchanger systems for just one chimney

- Fully automatic fuel detection and switchover

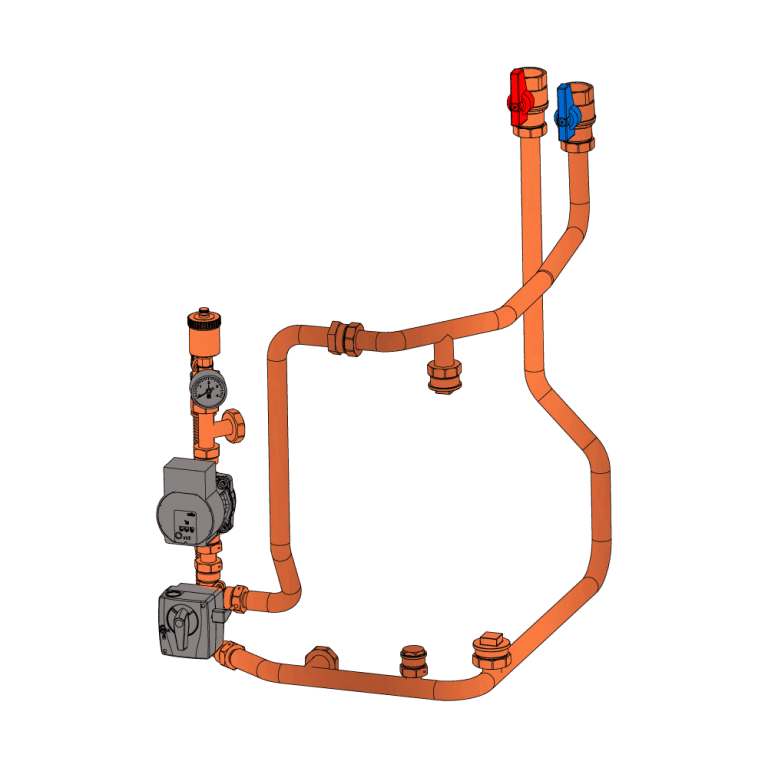

- Individual installation possibilities

- Energy efficiency class: A+

Our boilers in detail

Specifics

of Smart-HV & Smart-PK

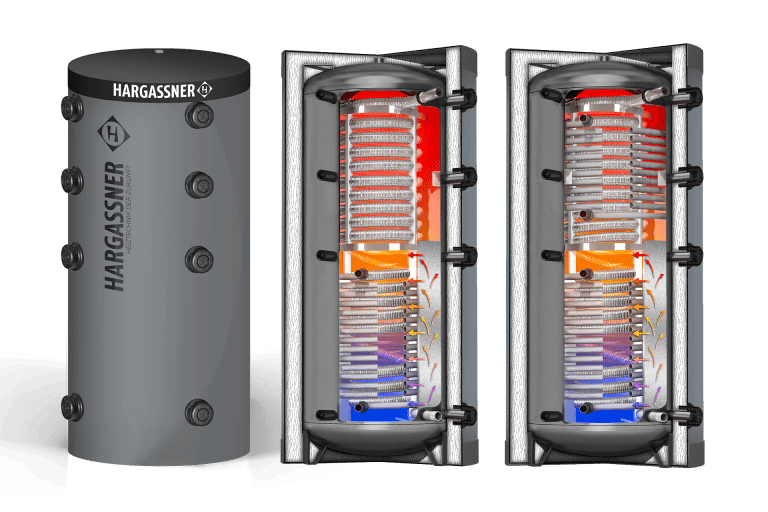

THIS IS WHAT A TOP PRICE-PERFORMANCE RATIO LOOKS LIKE IN 3D

Discover the entry-level combination Smart-HV 17-23 kW + Smart-PK 17-32 kW in advance by simply turning, tilting or tilting.

You can also discover this favourable combination variant in 3D right in your own boiler room. Simply click on the AR button and place, rotate and scale as you like using your smartphone or tablet and your fingers. You’ll get a quick impression of how you can integrate the Smart-HV 17-23 kW + Smart-PK 17-32 kW into your room.

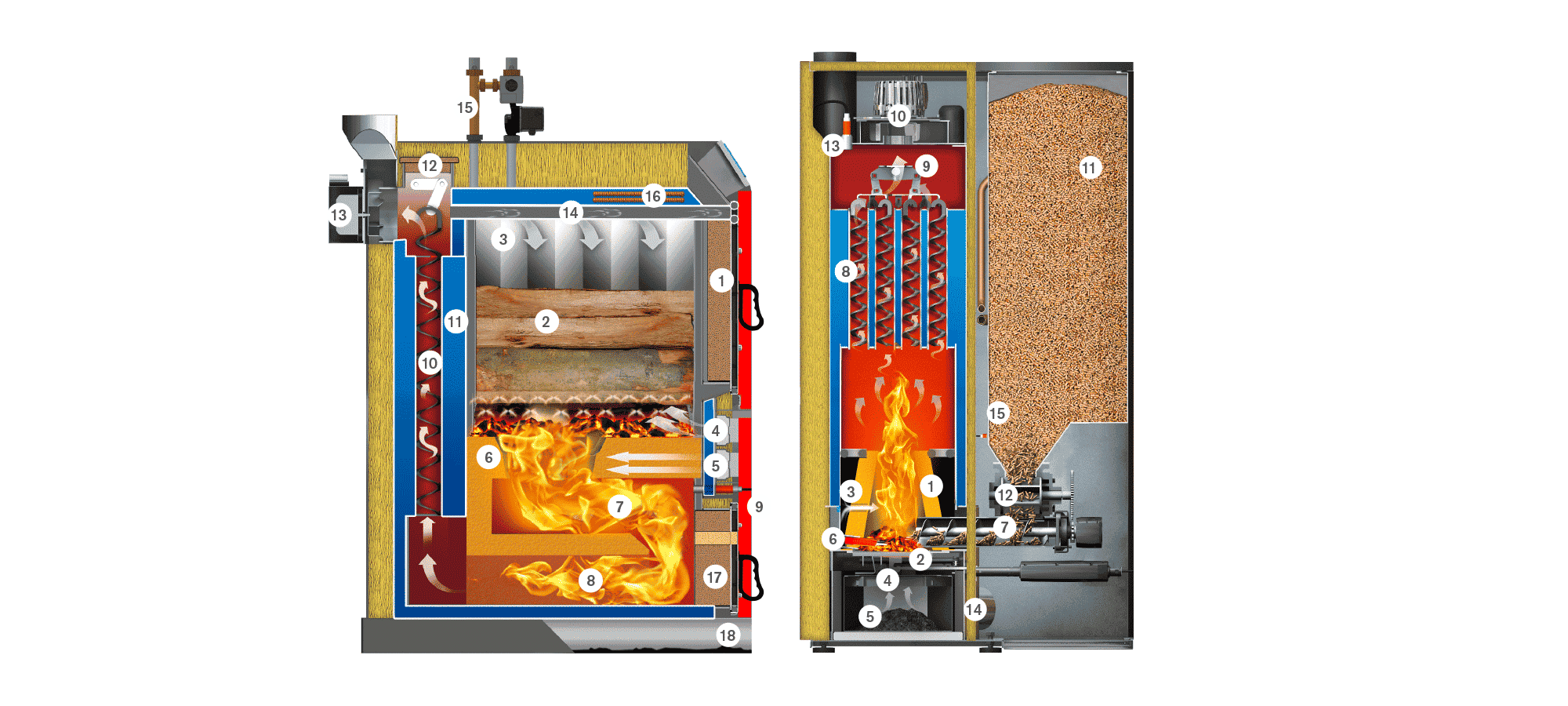

All technical details and important components can be found in the following sectional drawing.

Left: Smart-HV 17–23 kW

- Large filling door

- Filling chamber for ½ m logs (up to 53 cm)

- Combustion chamber lining – prevents tar formation

- Primary air motor

- Secondary air motor

- High-quality, massive refractory-lined combustionchamber

- High-temperature burnout zone

- Ash separation zone

- Lambda sensor

- Turbulators

- Heat exchanger

- Manual boiler cleaning device

- Exhaust fan

- Top smoulder gas ventilation

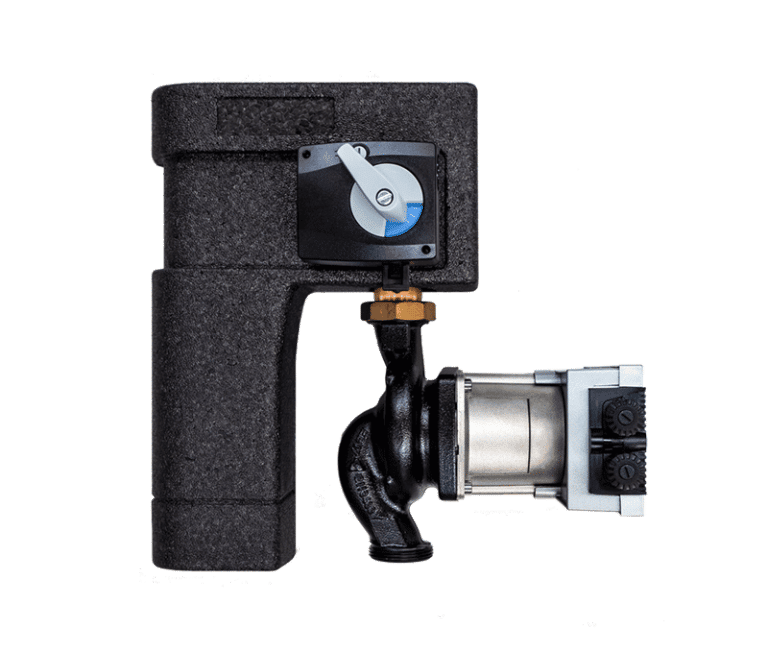

- Optional back-end protection

- Cooling coil for thermal safety circuit

- Cleaning door

- Ash pan

Right: Smart-PK 17–32 kW

- Fully refractory-lined combustion chamber

- Sliding grate

- Secondary air stream with inlet openings

- Primary air

- Ash pan

- Automatic ignition with 300 W

- Stoker auger

- Heat exchanger

- Turbulators with manual heat boiler cleaning system

- Exhaust fan

- Pellet day hopper

- Metering rotary valve

- Lambda sensor

- Air connection AIO / ADO

- Fill level indicator

A small insight

Target group

& possible areas of application

01

Contact us

Contact us for get some more

information and make an appointment!

02

Request

Our team looks forward to

hearing from you and providing

you with professional advice.

03

Appointment

We will inform you in detail

about our heating systems and the

corresponding heating supplies

for your biomass heating system.

04

Offer

We create an energy- and

cost-efficient offer that

is tailored to your needs.