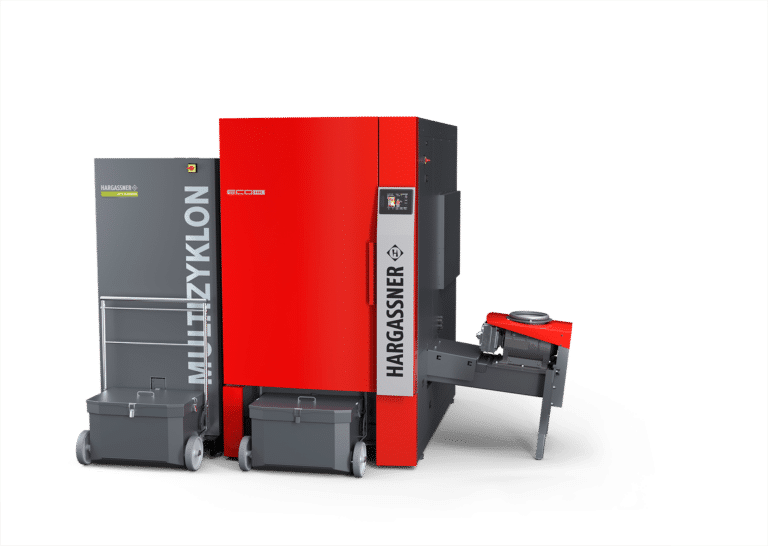

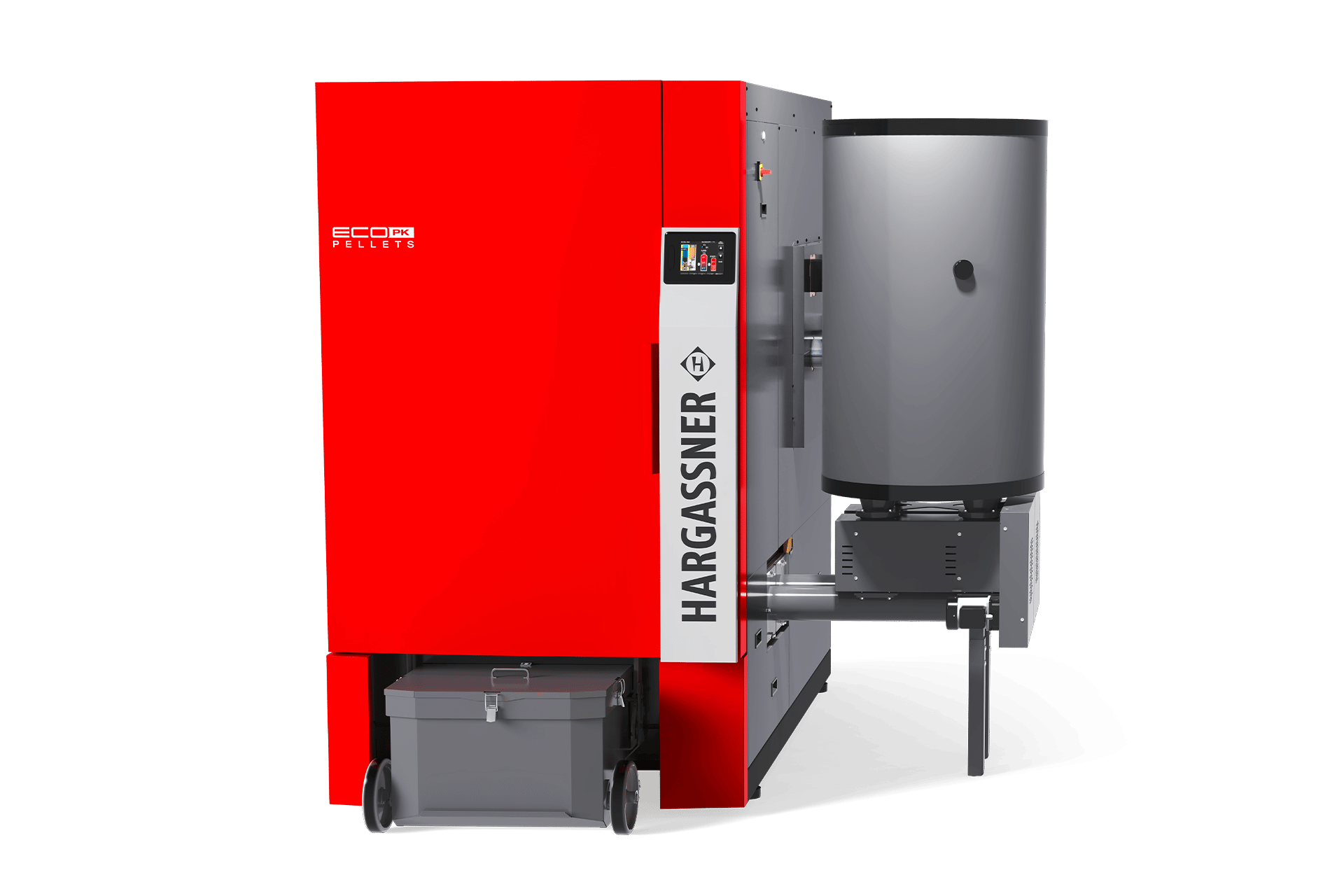

Eco-PK

250–330 kW

Sum of top heating solutions from Austria

- Fully automated

- Step grade system

- Cost-reducing eco mode

- Firebed level control with lambda sensor

- Up to 2 MW possible in cascade connection

High-temperature pellet boiler for the UK

Heating system for the large output range

The Eco-PK 230–330 kW pellet boiler is the most powerful boiler in the Eco-PK series. The high-temperature boiler is particularly suitable for use in the large output range such as multi-family houses, in the hotel / catering industry, in public buildings and for commercial and industrial operations.

The sophisticated and proven cutting-edge technology enables energy-saving, cost-cutting and fully automatic heating.

Benefits:

Eco-PK 250–330 kW

- Energy saving & cost reducing

- Highest efficiency

- Heat exchanger cleaning in 1st & 2nd pass

- Unique step grate system

- Fully refractory-lined combustion chamber for temperatures

- Lambda sensor with fuel quality detection

- Energy-saving ignition: 2 x 300 W

- Quadruple metering double rotary valve - 100% back-band safety

- Flue gas recirculation as standard

- Ember bed monitoring, contactless by means of sensors

- Flame & grate temperature monitoring

- Double insertion screw

- Constant capacity - no post-combustion before de-ash

- Induced draught (EC motor) with vacuum monitoring

- Integrated safety heat exchanger for thermal safety circuit

- Left-hand boiler version (return lift on the right)

- Mobile remote control - smart home app

- Modern touch display control

- 5-year warranty acc. warranty card

- Return lift can be integrated (optional)

- Automatic ash discharge (optional)

- Particle filter (optional)

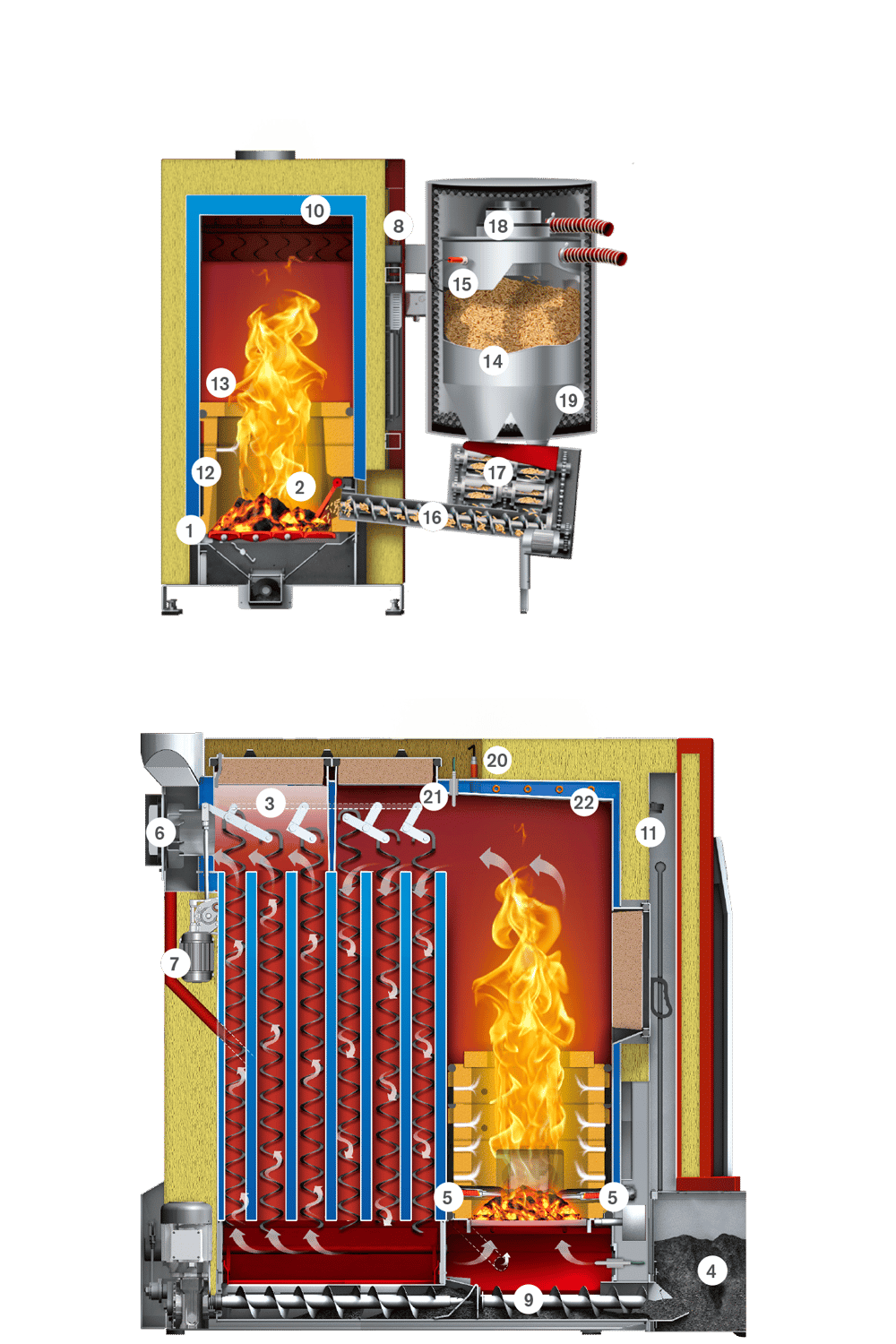

Our boilers in detail

Specifics

of Eco-PK 250–330 kW

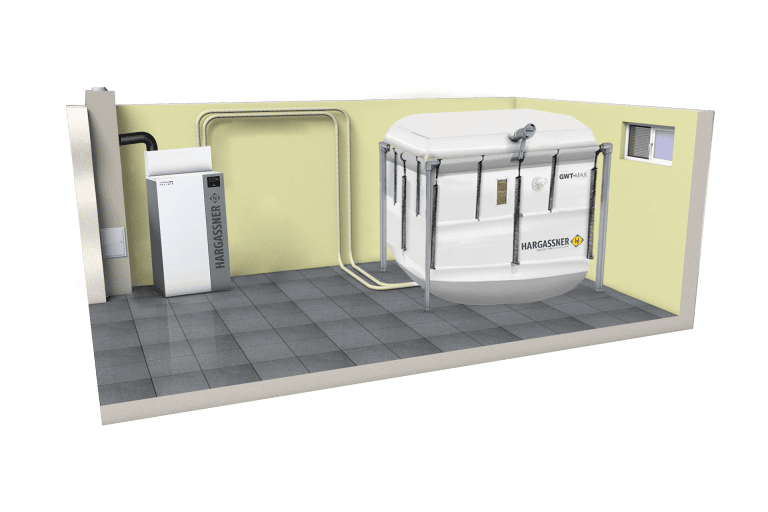

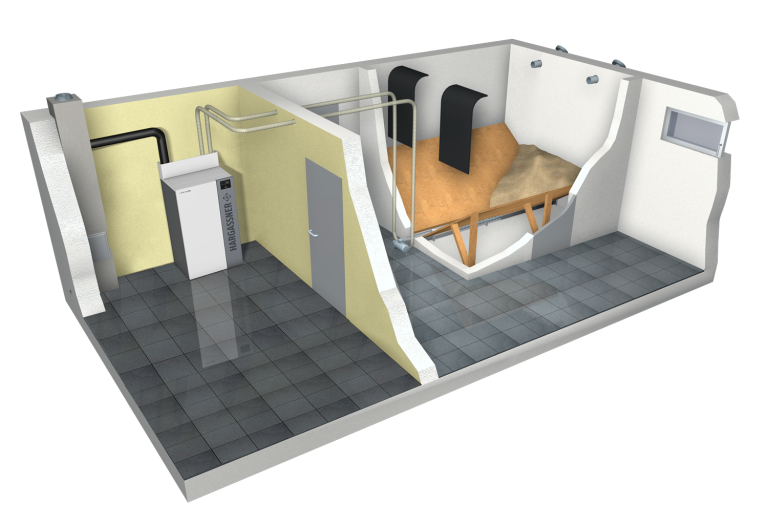

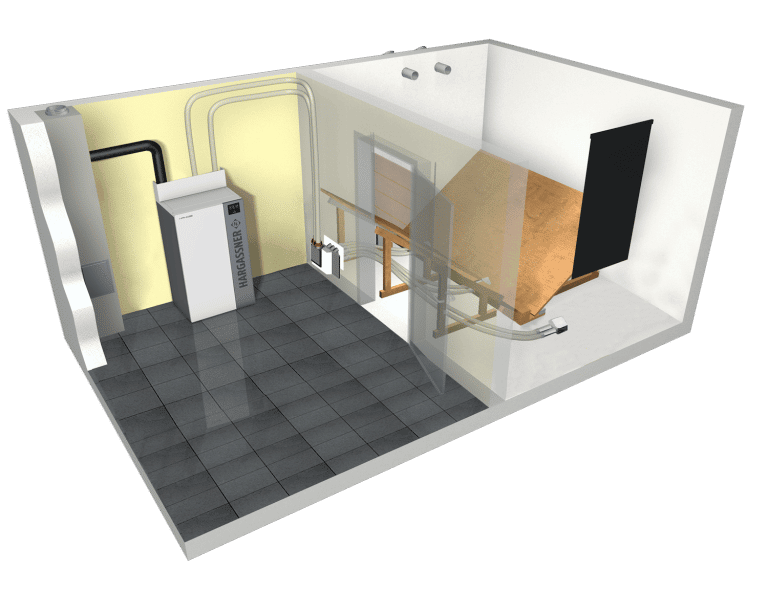

Admire the power package in powerful 3D visualisation!

Discover the most powerful high-temperature pellet boiler from all sides and in 3D. Turn, tilt or incline the Eco-PK 250–330 kW in all directions.

Experience this large boiler in your own future boiler room – right now on the screen. With augmented reality, you can place this bundle of energy in your future room. Simply click the AR button and place, rotate and scale it with your fingers. You will then have an exact impression of the integration of the powerful Eco-PK 250–330 kW into your room.

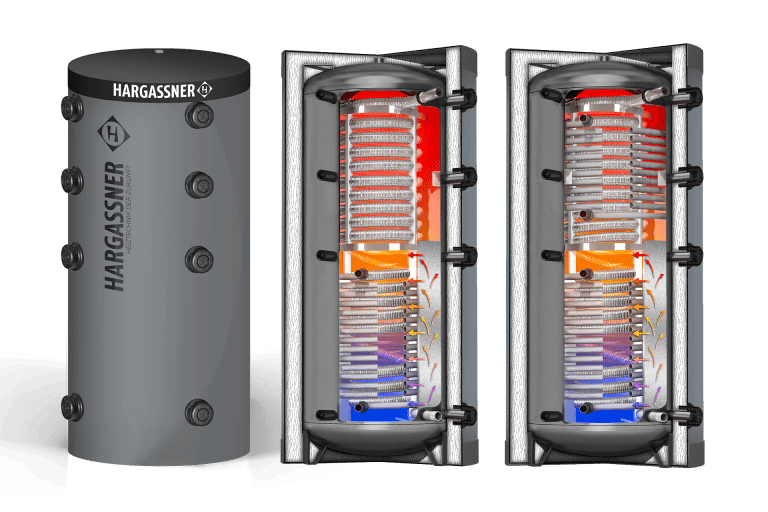

All technical details and important components can be found in the following sectional image.

- Step grate system

- Firebed level control

- Turbulators with automatic boiler cleaning device (also in 1st pass)

- Ash box (75 l)

- Automatic ignition with 2 x 300 W

- Exhaust fan (EC motor) with negative pressure monitoring

- Recirculation

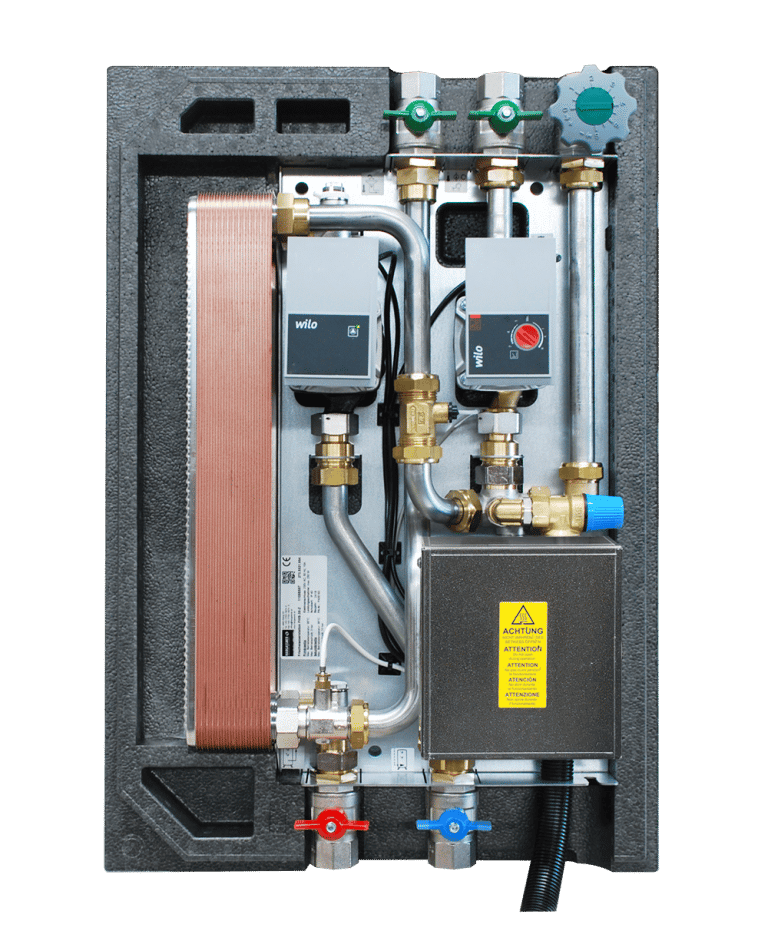

- Integrated back-end protection, optional

- Ash extraction system gor fly and grate ash

- Heat exchanger

- Negative pressure monitoring

- Fully refractory-lined combustion chamber

- Flame concentration plate made of high-quality refractory

- Pellet day hopper

- Fill level indicator

- Stoker auger

- Quadruple metering double rotary valve

- Pellet vacuum turbine

- Acoustic insulation

- Lambda sensor

- Flame temperature monitoring

- Cooling coil for therm. safety circuit

A small insight

Target group

& possible areas of application

01

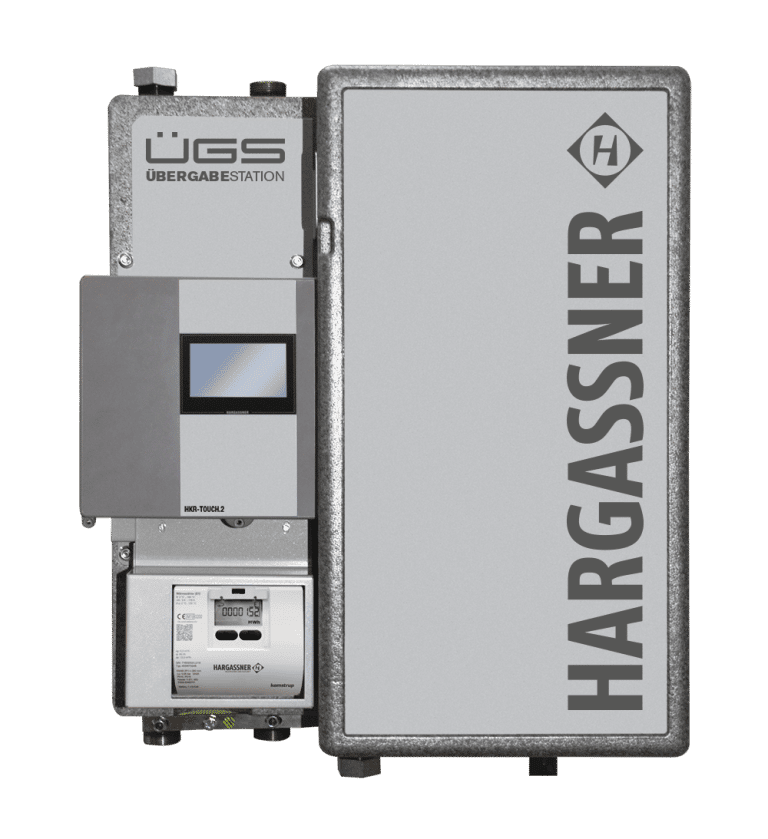

Contact us

Contact us for get some more

information and make an appointment!

02

Request

Our team looks forward to

hearing from you and providing

you with professional advice.

03

Appointment

We will inform you in detail

about our heating systems and the

corresponding heating supplies

for your biomass heating system.

04

Offer

We create an energy- and

cost-efficient offer that

is tailored to your needs.