Hargassner PowerBox

The warm-air module

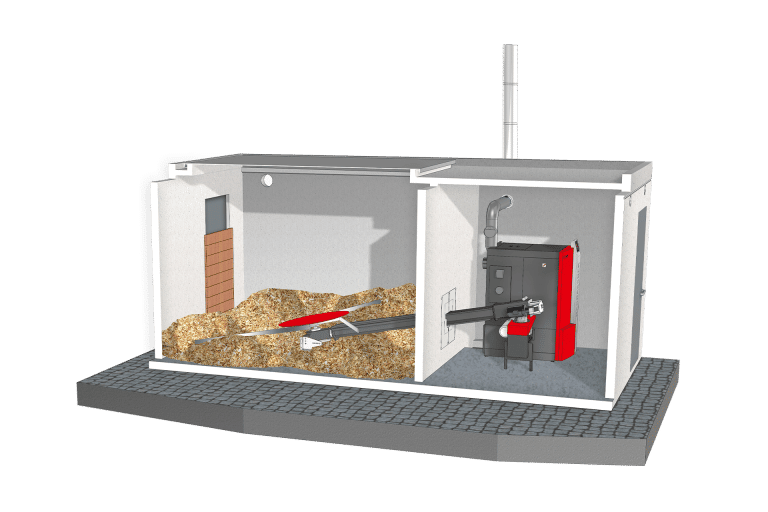

The Hargassner PowerBox is an efficient drying and heating system.

In summer it can be used for drying maize, cereals, hay or wood chips and in winter for heating purpose. The PowerBox is available with various outputs ranging from 100 – 220 kW and as a wood chip or pellet version.

It contains a Hargassner wood chip or pellet boiler that is water-based and ready to be connected. The boiler transfers its thermal energy to a large heat exchanger and a highly efficient centrifugal fan then generates the warm-air flow. Customers can therefore use their own fuel for low-cost drying, while the system is also climate-friendly and, thanks to the very economical water-based boiler, extremely efficient.

Another big advantage of the PowerBox is its mobility, which enables it to be used in the winter as a water- based heating system for residential buildings and barns, as a warm-air heating system for large tents or on building sites. Thanks to the freeze-proof features for water-based components, it is easily able to withstand outside temperatures as low as -20 degrees.

However, the boiler and warm-air heat exchanger can also be installed in fixed boiler rooms, which allows the total output to be increased up to 2,000 kW.

Application areas: Drying of hay, maize, grain, wood chips, drying out buildings, warehouses and commercial halls, greenhouses, event, festival and circus tents

Your Benefits

Heating module

Power-Box

- Compact design

- Efficient drying & heating system

- Very reliable & easy to maintain

- High efficiency and minimum fuel consumption

- Power range from 100 – 220 kW

- Total output can be increased up to 2,000 kW in fixed boiler rooms

- Remote monitoring possible with the app

- Low current consumption levels

thanks to a highly efficient speed-controlled radial fan

- Safe system:

Warm-air flow is decoupled from the firing system - Dual usage:

System can also be used as a water-based heating system - Freeze-proof at temperatures down to -20 °C

- Fully wired and ready to connect

- Filling in container or silo

- Operating hours meter / output meter for billing

Application areas

in the area of

Ideal application

- Drying of hay, maize, grain, wood chips

- Drying out buildings

- Heating of public construction sites

- Warehouses and commercial halls

- Event, festival and circus tents

- Greenhouses

Technical data Power-Box:

| Type | 100 | 120 | 150 | 170 | 200 | 230 | |

|---|---|---|---|---|---|---|---|

| Nominal heating output* | kW | 100 | 120 | 149 | 166 | 199 | 216 |

| Fan air flow (free outlet, no back pressure) | m³/m | 10000 | 10000 | 18100 | 18100 | 18100 | 18100 |

| Fuel wood chips – EN ISO 17225 | B1 bis A2 P16S-P31S M10-35 |

B1 bis A2 P16S-P31S M10-35 |

B1 bis A2 P16S-P31S M10-35 |

B1 bis A2 P16S-P31S M10-35 |

B1 bis A2 P16S-P31S M10-35 |

B1 bis A2 P16S-P31S M10-35 |

|

| Fuel pellets – EN ISO 17225-2 | A1 | A1 | A1 | A1 | A1 | A1 | |

| Weight | kg | ~2200 | ~2200 | ~3000 | ~3000 | ~3300 | ~3300 |

| Container | Fuss | 8′ | 8′ | 10′ | 10′ | 10′ | 10′ |

| Dimensions (L x W x H) | m | 2,4 x 2,2 x 2,3 | 2,4 x 2,2 x 2,3 | 3,0 x 2,4 x 2,6 | 3,0 x 2,4 x 2,6 | 3,0 x 2,4 x 2,6 | 3,0 x 2,4 x 2,6 |

A small insight