In 1983, Anton Hargassner Sr. decided to build a self-sufficient heating system for his wife. As the son of a farmer with a forestry business, he always had a connection with wood. This passion led him to develop the first automatic wood chip boiler.

Learn more about the beginnings of Hargassner – tradition and innovation in perfect harmony.

Rethinking heating

It was a promise that Anton Hargassner Sr. made to his wife Elisabeth in 1983: he would build her a more beautiful, more comfortable home. As the son of a farmer with a forestry business, he was familiar with wood and knew that it was a valuable raw material. In his mind, he knew that wood was the only suitable fuel for his new heating system.

The heating systems at the time were inadequate for him and his wife. Elisabeth Hargassner remembers that the constant refuelling was tiresome and dirty, that the firing technology was outdated, and that there was no comfort. So there was only one option: “Build it yourself!”

The principle was clear: it was to be a heating system that supplied itself with fuel — aka wood chips, a small-scale, largely standard fuel. Anton Hargassner developed the first automatic fuel logistics system for wood, with a storage hopper and fuel extraction system via auger directly into the combustion chamber. After much tinkering and testing, the creation was successful: the first Hargassner wood chip boiler was a hit — not just with his wife!

"I want a heating system like that!"

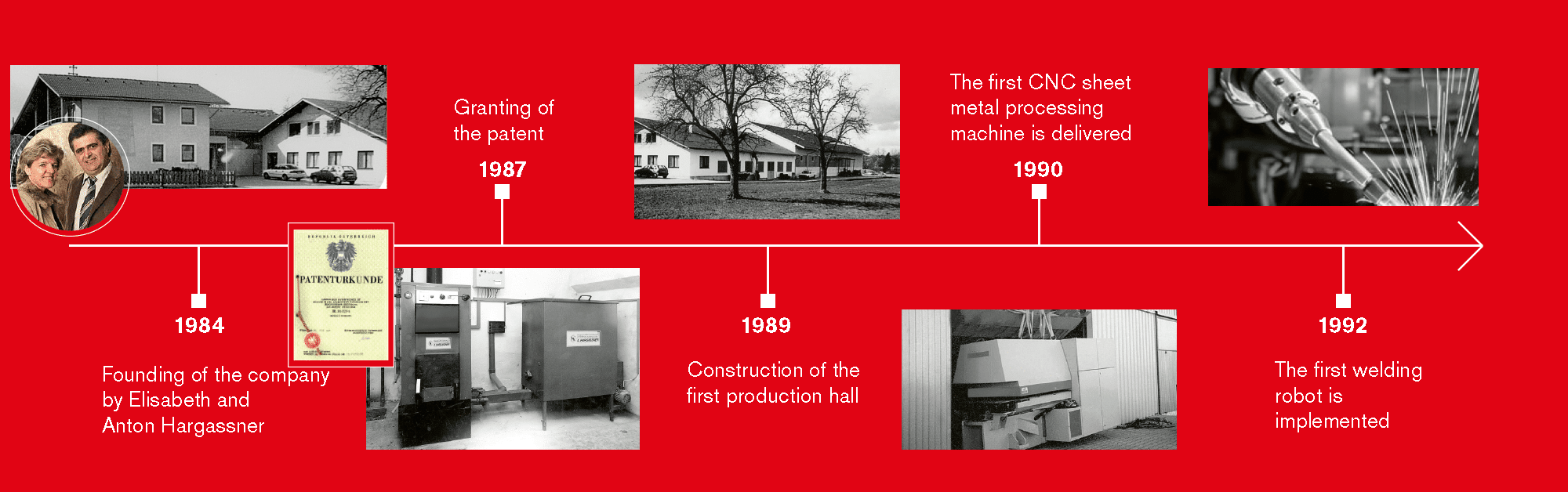

After recognising the potential of his new development, Anton Hargassner set about perfecting his fully automatic carburettor combustion system and applied for a patent. The next steps were obvious: register the business and start production. There were quite a few competent voices trying to convince the young entrepreneur that he was backing the wrong horse: “Forget wood – the future belongs to oil and gas heating!” Anton Hargassner was not deterred, as he was convinced that wood was the ideal fuel for farmers and that it was only a matter of making it easier for them to utilise their natural resources with modern heating technology. “I will bring comfort into the farmers home’s” – that was his motto.

Perseverance and staying the course

Unfortunately, despite the initial interest, sales fell a little short of expectations. Production ran at full speed during the week, and sales were made at the weekend. One question came up again and again: How do I get my wood chips?

Wood chipping machines were not yet widespread at the time, so a solution had to be found at short notice. Buy a wood chip boiler; borrow a chipper. Hargassner bought a chipping machine and thus offered every customer the security of being able to process the wood from their forestry operations into wood chips in a timely and cost-effective manner.

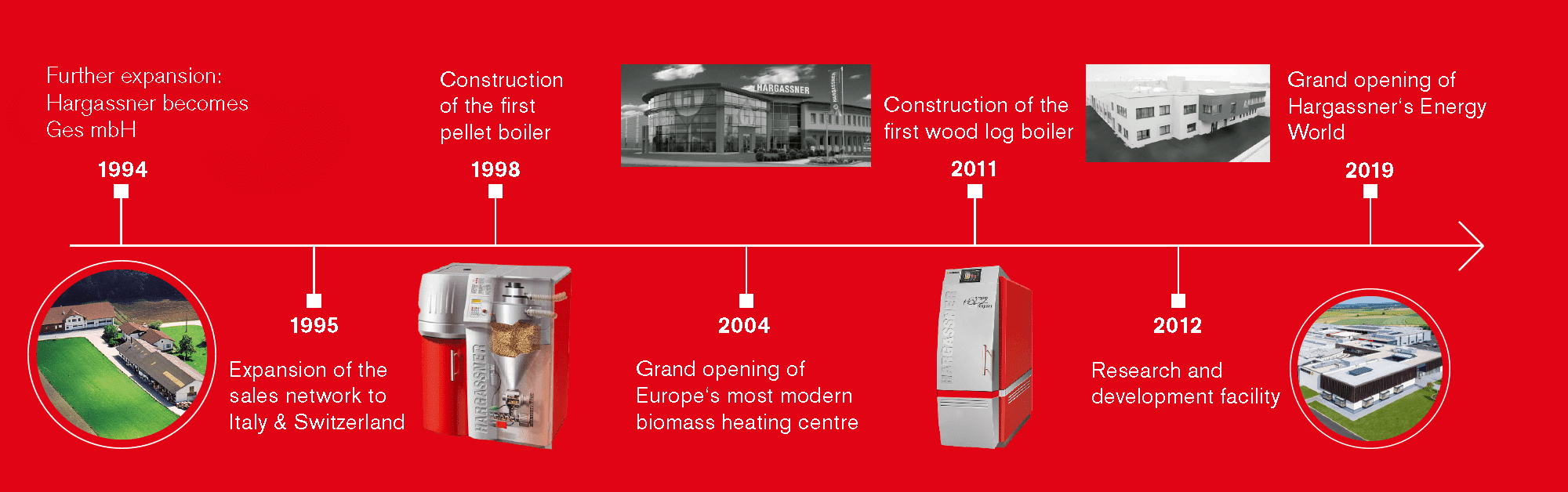

Since its humble beginnings in 1984 with the introduction of guillotine shears and metal folding machines, Hargassner has consistently invested in the latest cutting-edge machinery. From the pioneering use of CNC technology for sheet metal processing to the adoption of CNC lathes and milling machines, Hargassner has always embraced technological advancements to enhance its production capabilities. While the demands of modern production are constantly evolving, Hargassner has maintained a harmonious balance between technological innovation and the value of its human workforce. As the number of machines has increased, so has the number of employees. Hargassner recognises that its long-serving employees are the heart of its operation, contributing to the quality of its products and fostering a positive and productive work environment. Hargassner’s approach to production automation is not about replacing human workers with machines but rather about leveraging technology to complement and enhance the skills and expertise of its employees. This symbiotic relationship between humans and machines ensures that Hargassner remains at the forefront of its industry while upholding its commitment to creating a workplace where employees thrive.

Farmer Ludwig Schaller, Mining Austria

The first

Farmer Ludwig Schaller put his trust in Anton Hargassner’s innovative spirit and became his first customer. His heating system ran problem-free for over 19 years thanks to Hargassner’s great maintenance. The system was only replaced in 2003 (!): Ludwig Schaller received the newest model of Hargassner’s wood chip heating systems, his “old model” can be seen by all interested parties in the new biomass experience world in the Hargassner Energy World as a symbol of the pioneering days of Hargassner heating technology.

Small anecdotes from companions

A vision 40 years ago!

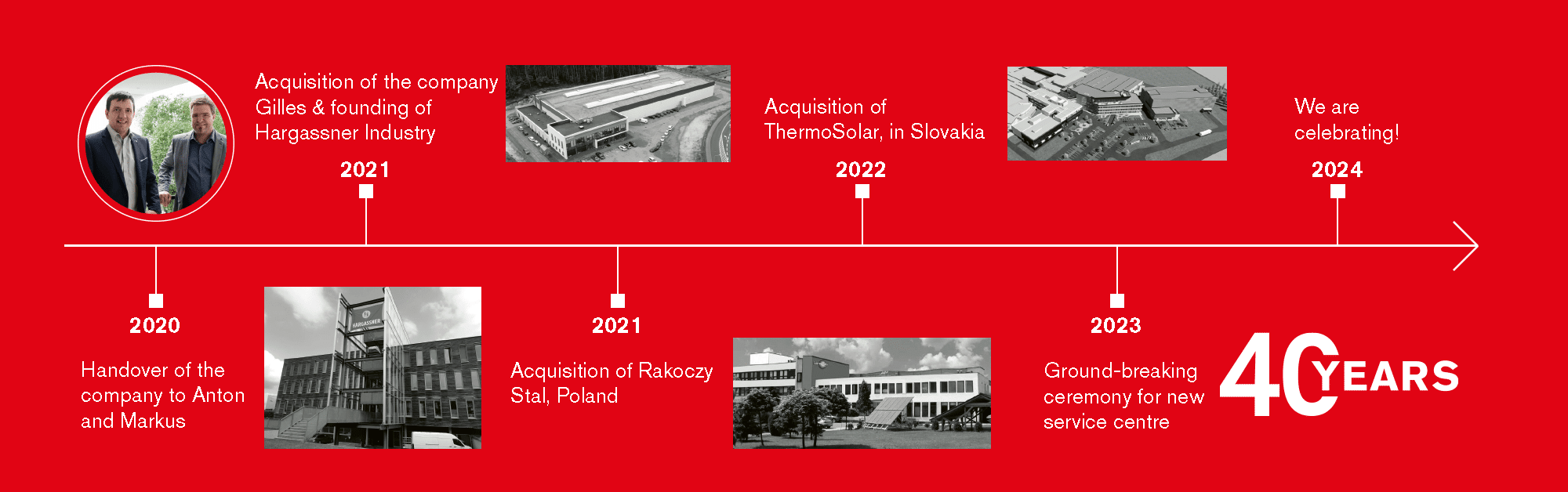

“40 years ago, we could never have imagined what this invention would one day become. We would like to thank all of our employees.

Special thanks go to our sons Markus and Anton, who continue to run the company in our spirit and with a lot of hard work and energy. We wish you all the best for the future,” said Anton Sr. & Elisabeth Hargassner.