The top heating performances

Particle separator

Reduce your particulate emissions! Choose the right system for you from the various particle separator.

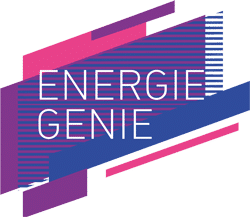

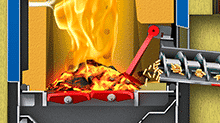

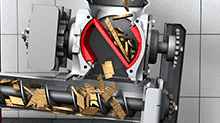

Double Rotary Grate: 1. Grate Movement

The grate consists of two consecutive and stepped grates which can move independently. During combustion the grates are moved accurately to ensure a homogeneous firebed.

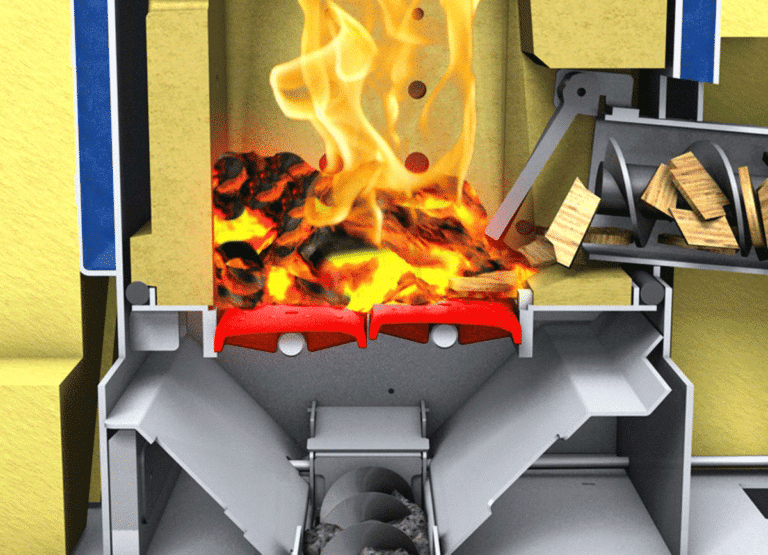

Double Rotary Grate: 2. Rear Rotary Grate

Pellets as well as Micanthus can be combusted easily. If regular wood chips are used, only the rear de-ash grate opens. Ash is falling down and embers remain.

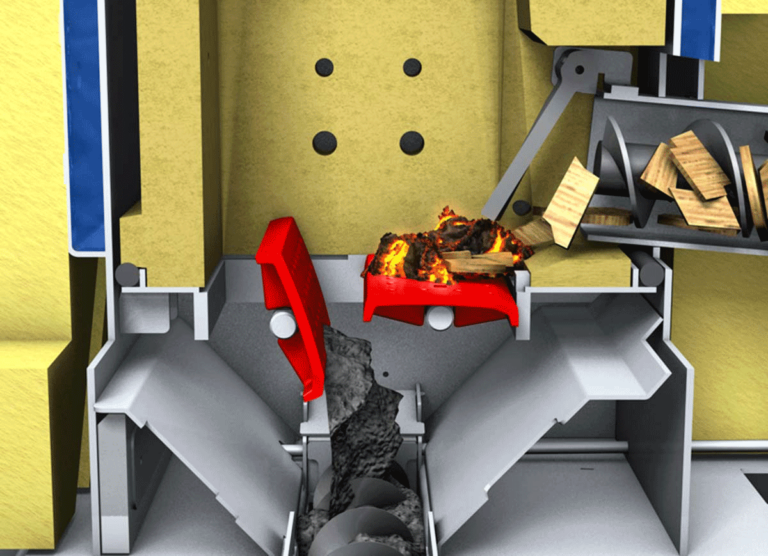

Double Rotary Grate: 3. Open Both Grates

If the boiler is completely cold a full cleaning process is executed prior to start. Both grates open, cold ash and all foreign objects like stones, nails, etc. are being disposed.

Double Rotary Grate: 4. Breaker Function

For miscanthus etc, the “Breaker Function” of the grate forces clinker down into the ash auger.

Highest efficiency of the boiler

With highest efficiency , Hargassner Wood chips boiler are beneficial for lowest fuel consumption as well as with lowest emissions.

5 years warranty

3 or 5 years warranty on material (depending on type of boiler) on electrical parts or gear boxes. 3 years warranty (material, working hours, travel expenses) on the boiler.

Lambda sensor with fuel quality detection

The control unit uses the lambda sensor to detect the relevant calorific value and regulates hat optimal fuel / air mixture.

Control 'Lambda-Touch-Tronic'

The unique boiler control with touch screen offers the most modern user-comfort and controls the whole combustion process. Furthermore, all heating circuits are regulated by outside-temperature control and the HWT is controlled with a temperature-difference-regulation.

Hargassner App

Adapt your boiler quick and easy. Change settings on heating circuits, heating times, temperatures, …

Fully refractory-lined combustion chamber

Refractory Lined combustion chamber guarantees high combustion temperatures through optimum heat storage (already at part-load), which minimises the irgnition procedure and recduces emissions.

Firebed monitoring

Through the exact and contact-free firebed-height monitoring system with sensors, the most effective combustion condition (depending on fuel quality) is detected. Your heating system is always working withi the required heat output at optimal combustion values.

Integrated Back end protection

An integrated back end protection with energy-efficient pump and motor mixer is available.

- quick and easy assembling

- compact and not expensive

Fluegas - Recirculation Standard Feature

To reduce clinker creation in the ash, Hargassner offers a flue gas recirculation, especially for very dry fuel or material with a low ash melting point. The resulting ash can be easily removed out with the ash extraction auger.

Integrated Touch Control

The control system is characterised through its exeptional design and simple handling. Navigation is very sophisticated. You visually recognise the current status of the boiler, the accumulator and HWT as well as all heating circuits.

Automatic Ash Extraction System

The all new ash extraction systems results in very long maintenance intervals. The ash-box can be mounted left and right hand side of the boiler. Consists out of a 300l ash-box and flexible auger.

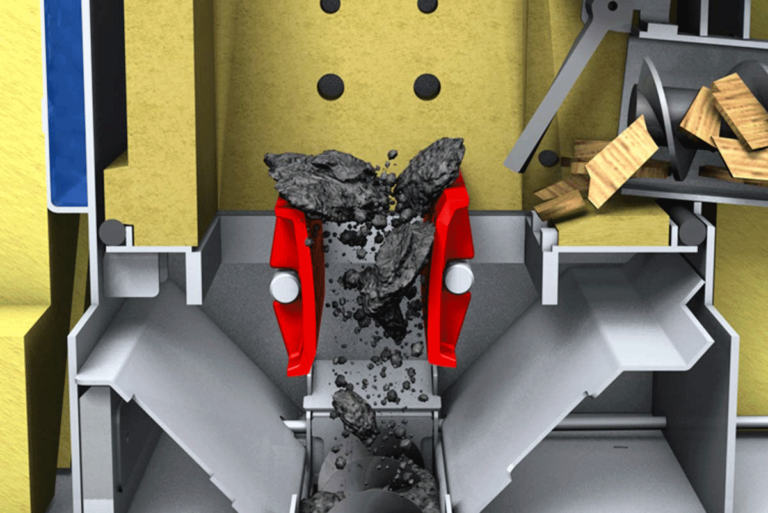

Z-shaped rotary valve

The Z-shaped rotary valve is designed specifically for wood chips. Guarantees 100% burn-back safety, Depth of chamber 18 cm. Especially for extra long wood pieces with smooth operation. With hardened cutting edges.

News, References, Events & more

Discover the world of biomass and get all the latest news about the heating manufacturer HARGASSNER. We offer solutions for a wide range of industries - from private households to agriculture & forestry to commerce & industry.