Pellet heating system

Comfort, efficiency, environmental friendliness – these are the features that characterise Hargassner’s pellet boilers. As with all our biomass heating systems, flexibility and a wide range of variants are also a top priority for our pellet heating systems: this is how we ensure that there is a suitable wood pellet heating system for every need. We are proud that our Nano-PK and Smart PK boiler series which won the “Energiegenie” Innovation Award in 2020. This underlines our unwavering commitment to innovation and excellence in heating technology.

Nano-PK

What makes it unique

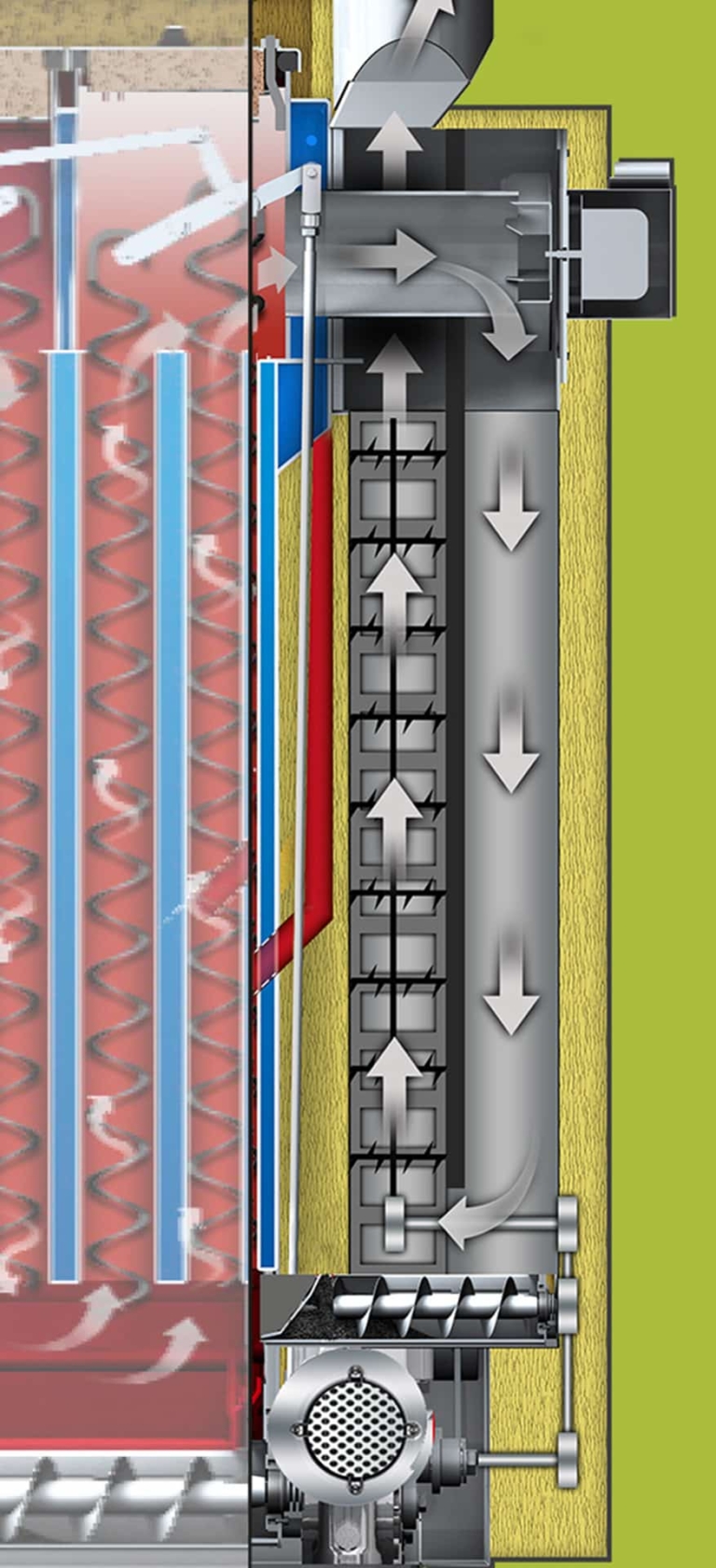

The Nano series of pellet boilers from Hargassner is the right choice for those looking for maximum convenience and high heating output. The “Nanos” require little space and can even be installed in a niche in small utility rooms. The fully automatic technology ignites and cleans itself. It independently maintains the desired room temperature and you can enjoy cosy warmth yourself.

Small, compact design

Can be fitted flush with the wall on three sides, making it perfect for compact heating or installation rooms. Depending on your local building codes, it is no longer required to be installed in a separate boiler room.

minimum space requirement:

0.45 m² (for Nano-PK 6 – 15) or

0.69 m² (for Nano-PK 20 – 32)

Quick to transport

The Nano-PK boiler is a single-unit system, making it easy to transport. In most circumstances, disassembly is no longer necessary.

Quick installation

All accessories and pipework are installed in the boiler and ready for connection. All connected components, including the flue pipe and pellet transport pipes, run upward and away from the boiler. Easy installation saves you time and money!

Maintenance openings easy to access

All of the boiler’s components are positioned such that they may be easily accessed from the front or top.

More benefits of the Nano-PK

- Air-independent operation is standard

- Highest efficiency

- Fully automatic operation, including ignition, cleaning, and de-ash

- Energy-saving ignition with 300 watts

- Flue gas recirculation is standard

- Circulation zone for complete post-combustion

- Variable flue pipe connections (left, back, and top)

- Fine dust filter (optional).

- Prepared for extension with a condensation heat exchanger (upgrade to Nano-PK Plus).

- Integrated hydraulic module (optional).

- Five-year guarantee acc. warranty card

- Energy efficiency rating: A+

Nano-PK

The future of heating

Most efficient

low-temperature boiler

The Nano’s usable output range for the heating water circuit is low to high temperature. In modern heating systems, an exterior temperature sensor automatically changes the boiler output to meet the present heat demand. Heating water temperatures that can be reduced to around 40°C are frequently required in economical constructions or during transitional periods. As a result, the low-temperature boiler always produces only the amount of heat required for the radiators. This avoids radiation losses and reduces power loss through the chimney.

Practical

consumption display

A dependable reminder on the display, remote control, mobile phone, or tablet will automatically notify you when the pellets need to be replaced.

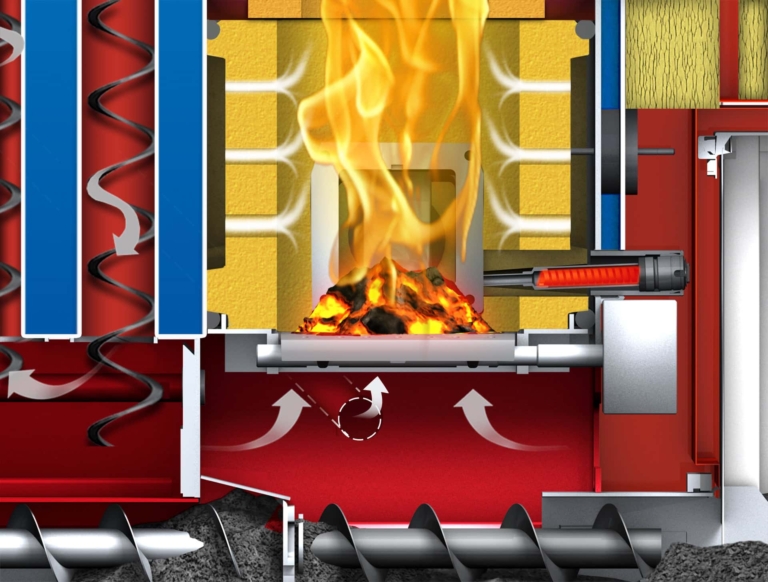

Fully refractory-lined high-temperature combustion chamber with a lambda sensor

Refractory has proven itself as the best material available in terms of heat storage, function and durability. The high combustion chamber temperature at full and partial load contributes to very good combustion efficiency of up to 96% and low emission values. The lambda sensor regulates exactly the right quantity of fuel in every output range according to the pellet quality. This guarantees economical and low-emission combustion.

Automatic pellet transport

The hopper of the boiler is automatically replenished at predetermined times and as needed. A turbine powers a suction system that carries pellets from the fuel extraction system to the hopper. With suction hoses, pellets can be carried up to 20 metres from a storage area. A metering double rotary valve in a cast construction provides 100% burn-back protection through pressure adjustment. The gasoline passes via the rotary valve and into the feed auger. This transfers the pellets directly to the combustion chamber.

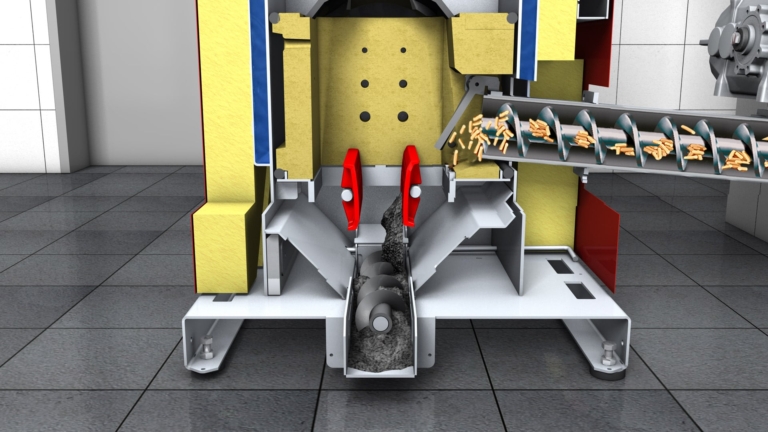

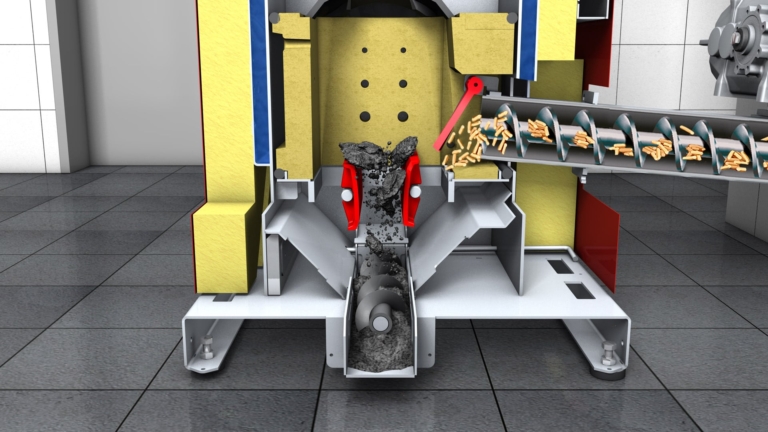

Intelligent ash disposal

The ash is compacted by a distribution mechanism on the sliding grate and filled to the pan’s last corner. This allows for significantly longer emptying intervals. The boiler’s display, remote control, or mobile devices all consistently indicate when the pan needs to be emptied. A filled reserve offers you approximately another week. This is Hargassner pellet heating comfort! Depending on the heating duration, the heat exchangers are automatically cleaned. This removes residue from the boiler walls, which falls directly into the ash pan. The ash is discharged from the Nano-PK 20 – 32 via a transport auger and an ash box.

Benefits of the large-scale pellet boiler series up to 330 kW

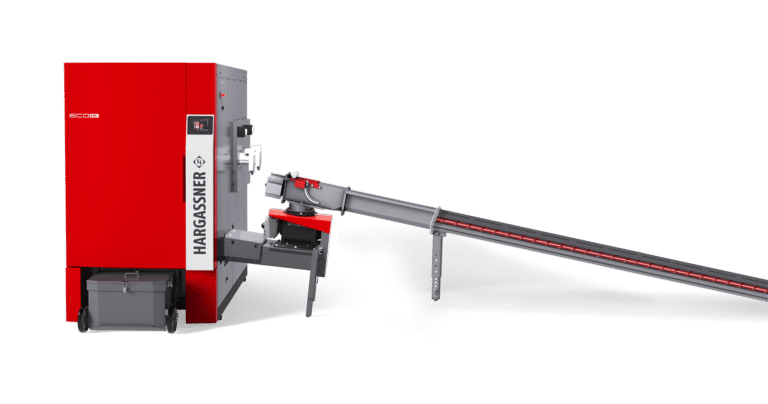

Eco-PK

The Eco series pellet boilers are ideal for any application that requires medium to high heating output. If up to six boilers are connected in cascade, or in series, an output of up to 2 MW is feasible. This is cutting-edge heating technology, complete with numerous energy-saving features, allowing heat to be produced with fewer emissions and at a lower cost when energy demands are high. The “Ecos” represent effective and efficient heating.

Energy-savingEco operation

Speed-controlled EC exhaust fan with negative pressure control

Hargassner’s Eco-PK boilers have energy-saving EC exhaust fans. The key advantage of this GreenTech EC technology is its much improved efficiency of up to 95%. This saves energy, which reduces power expenses. The negative pressure unit constantly monitors the pressure inside the combustion chamber. The “Lambda Touchtronic” control software manages the speed of the exhaust fan, keeping the negative pressure at an optimal level. This idea ensures combustion with the lowest possible emissions, resulting in maximum efficiency.

Energy-saving ignition

The innovative design of the ignition element has decreased power consumption to only 300 W (up to 1,000 W less)* while increasing ignition process efficiency.

- Energy savings of more than 88 %

- Smart ignition monitoring

- Silent operation

One boiler – two options

Suction extraction system with dayhopper for pellets

The wood pellets are suctioned from the fuel storage chamber, briefly stored in the day hopper, and fed into the boiler using a double rotary valve.

Direct fuel extraction system (RAP) for pellets

A direct auger transports the wood pellets from the pellet storage area to the boiler.

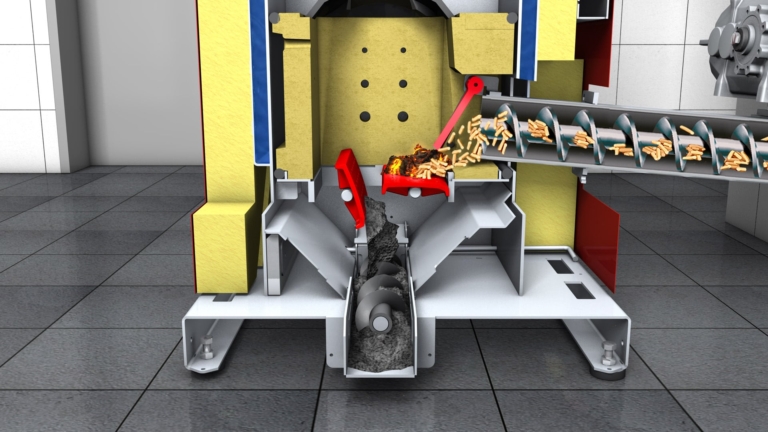

Eco-PK Strong step grate

Closed grates in the combustion chamber with a high firebed – optimises the gasification process and minimises micro-dust emissions.

During the heating cycle, just the rear rotating grate is opened for the de-ash process. The ash falls, leaving leftover embers that allow the newly extracted fuel to be burned again.

The combustion chamber is thoroughly cleaned before the boiler is restarted. Both grates are open, and cold ashes and extraneous materials like stones or nails are disposed of.

For fuel with a particularly low melting point, the rotary grate’s extra “breaker function” will break the clinker.

Sophisticated technology

Eco-PK

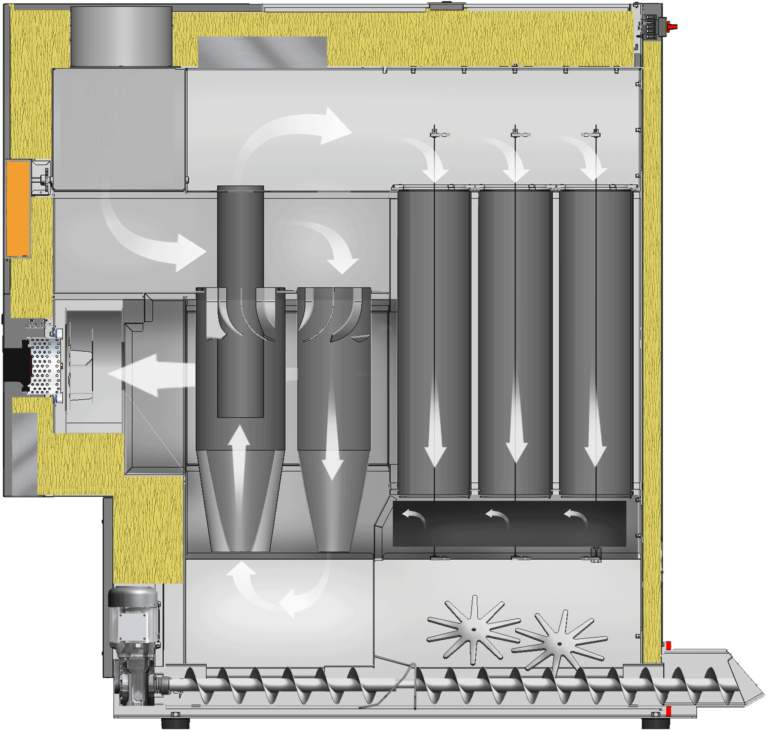

Fully refractory-lined combustion chamber with standard recirculation

The refractory combustion chamber’s excellent storage effect ensures high combustion temperatures (even at partial load), decreases the number of times the boiler must be started, and lowers pollutants. Every Eco-PK comes with flue gas recirculation as standard to prevent ash clinkering caused by dry fuel or fuel with a low ash melting point. Cooling the firebed prevents low-grade fuel ash from melting. The residues can then be readily disposed of with the ash extraction system.

Automatic pellet

transport

The hopper in the boiler is automatically filled. A turbine powers a suction system that carries pellets from the fuel extraction system to the hopper. With suction hoses and air, wood pellets can be carried up to 20 metres from a storage chamber. A metering double rotary valve made of solid steel offers complete protection against burnback. A steady amount of fuel passes through the rotary valve and into the feed auger. This transfers the pellets directly to the combustion chamber.

Optimised cleaning for high convenience

ALL heat exchanger pipes – including the first pass – are cleaned at regular intervals. The edges of the auger turbulators efficiently remove any fly ash residue from the boiler pipes and this drops straight onto the ash auger. Both the fly ash and the grate ash are transported into a fully integrated ash box by just one ash extraction auger. The residues are crushed as they are being transported and then compacted in the box, resulting in increased annual efficiency and a higher degree of cleaning convenience. With Eco-PK 70 – 230, only one drive is required for heat exchanger cleaning and ash extraction. Optionally, there are also different ash transportation systems in a 240 or 300 l ash bin.

Independent firebed monitoring

Non-contact sensors monitor the firebed’s height, ensuring the most efficient combustion conditions.

Lambda sensor control

The lambda sensor included into the control unit determines the calorific value of the fuel and so regulates the ideal fuel/air mixture.

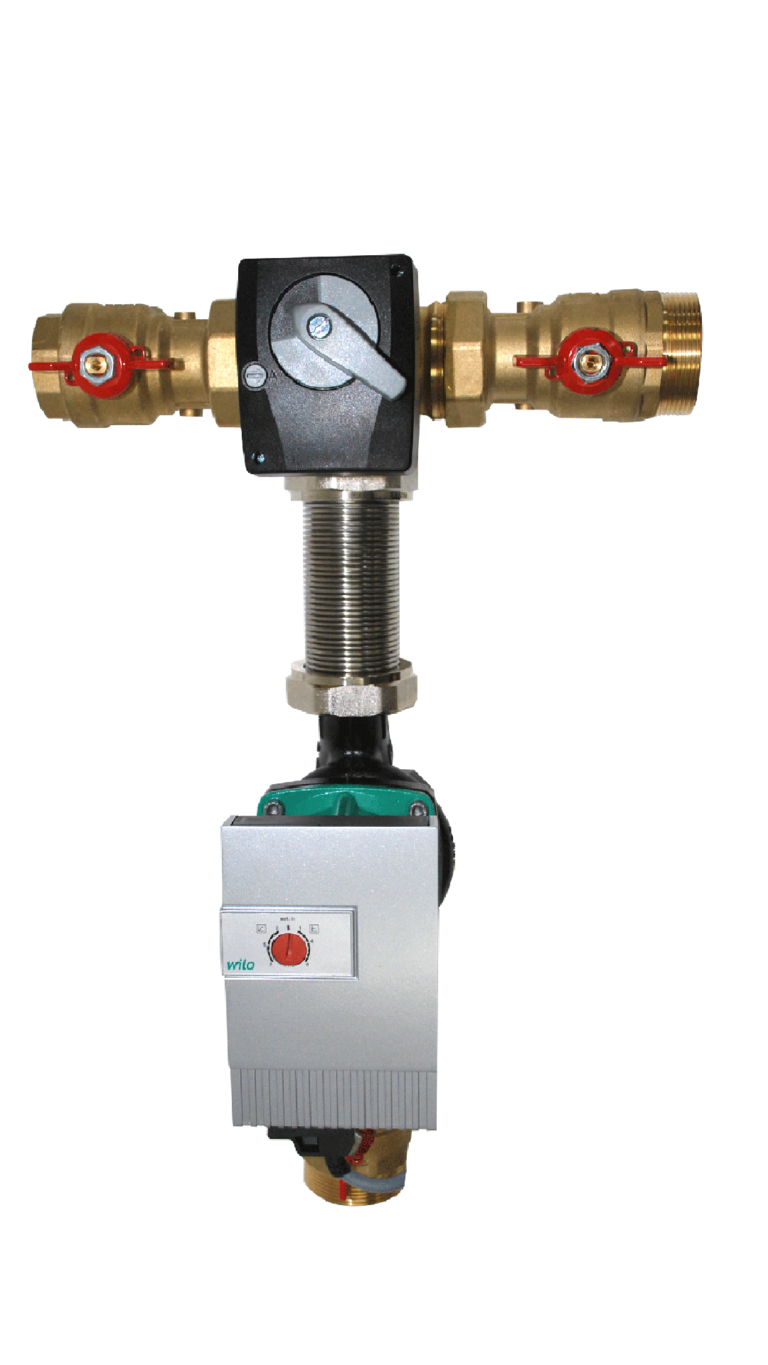

Integrated back-end protection

An integrable back-end protection with energy-saving pump and motorised mixer is available as accessories.

- Quick and easy installation

- Compact and cost-effective

Particle filter

eCleaner

The Multicyclone & eCleaner particle separator operates on the electrostatic principle and is designed as a centrifugal separator. The electric field channels the flue gas through the pipes, while fine dust particles gather on the separator pipe’s inner wall. The separated dust is removed from the separator pipes via sliding valves and discharged into the collection area.

Filter technology

Unique filter technology

The filter will greatly reduce your boiler’s microdust emissions, depending on the quality of the fuel it uses. Electrostatic particle charging occurs in the eCleaner. They accumulate on the walls and fall through the automatic cleaning mechanism. An auger transports them to the boiler’s ash box.

- Low space need

- Micro-dust emissions are reduced

- Automatically clean and transport to the ash tray

- Optional, easily retrofitted at any time

Multizyklon

Combined with eCleaner

- Specially for Eco-PK & Eco-HK 130–330

- Total dust minimised

- Accessories: Large ash box

75 litres or AFS with 240 litres or 300-litre bin